Ultimate Technical Guide — Hot Plate Welding Machine & Industrial Plastic Welding (Dizo Sonics)

Comprehensive technical reference for engineers, buyers and production managers. Covers hot plate welding machines, plastic pallet welding, ultrasonic welding, vibration welding, infrared welding, design-for-weld, process parameters, quality control, automation and case studies. Internal resources: Products • Technology • Contact Us.

Executive Summary

Hot plate welding machines remain the preferred industrial method for joining large, thick, or structural thermoplastic parts where airtightness, mechanical strength and long-term reliability are required. This guide explains the engineering principles behind hot plate welding, compares common plastic welding methods, provides application selection logic, process parameters, quality assurance methods, and integration strategies for smart factories.

Primary keywords covered naturally in this article: hot plate welding machine, plastic welding machine, plastic pallet welding machine, ultrasonic welding machine, vibration welding machine, hot plate plastic welding machine.

Note: For product inquiries, samples and technical evaluations, use our contact page: https://dzsonics.com/en/contact-us/

1. Why Industrial Plastic Welding Matters

Thermoplastics such as PP, PE, HDPE, ABS, PC, and PA are fundamental to modern manufacturing due to weight, corrosion resistance and cost advantages. However, joining thermoplastic parts reliably at scale requires controlled thermal bonding — achieved by the modern plastic welding machine.

Hot plate welding, ultrasonic welding and vibration welding are widely used; each covers different design and production needs. Choosing the correct method impacts product lifecycle, production cost, and field reliability.

1.1 Common Use Cases

- Plastic pallets and logistics containers (hot plate welding for thick ribs and runners)

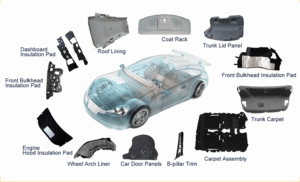

- Automotive interior/exterior modules (bumpers, HVAC housings, reservoirs)

- EV battery housings and cooling components (seal integrity)

- Household appliance tanks and bins

- Medical device housings where no adhesives are allowed

2. Overview of Welding Technologies (Selection Logic)

Below is a high-level comparison to help decide which technology to evaluate first:

| Technology | Heating Method | Best For | Limitations |

|---|---|---|---|

| Hot Plate Welding | Direct conductive heating (heated platen) | Large, thick-walled thermoplastics; airtight tanks; pallets | Medium cycle time vs ultrasonic; requires fixtures |

| Ultrasonic Welding | High-frequency vibration | Small-to-medium precision parts; fast cycles | Poor on thick parts and GF-filled materials |

| Vibration Welding | Linear friction between parts | Large PP parts with flat joining surfaces | Not suitable for complex enclosed geometries |

| Infrared Welding | IR radiation (non-contact) | Cosmetic parts requiring no contact marks | Optical/absorption limitations; higher capital cost |

| Spin Welding | Rotational friction | Round connectors, small tanks, circular seals | Geometrically limited |

Authoritative primer on plastic welding: Wikipedia — Plastic welding.

3. Hot Plate Welding — How It Works (Engineering View)

Hot plate welding melts the mating surfaces with a heated platen. After achieving the required melt condition, the platen retracts and the parts are pressed together under controlled pressure to form a fused joint.

3.1 Four Key Phases

- Loading & clamping — Parts are precisely positioned in fixtures.

- Heating (melt) — Heated platen contacts part faces and melts the surface layers.

- Retract & joining — Platen retracts and parts are pressed together under a controlled force profile.

- Cool & release — Parts cool while held; pressure profile ends and part is released.

Key control loops: platen temperature (multi-zone PID), displacement control (servo or precision pneumatic), and force/pressure monitoring. Data logging of these signals provides traceability and supports QC gating.

For product options see: Plastic Pallet Hot Plate Welding Machine and Dizo Sonics products.

4. Materials & Melt Behavior

Welding behavior depends on polymer class (crystalline vs amorphous), melt flow index (MFI), fillers (glass fiber), and thermal stability. Typical engineering plastics:

- PP (polypropylene) — crystalline; common for pallets and tanks; needs controlled cooling to avoid warpage.

- HDPE / PE — high toughness; requires temperature control to avoid oxidation.

- ABS / PC-ABS — amorphous blends used in cosmetic parts; careful heat to prevent visible marks.

- PA (polyamide) — hygroscopic; must be dried and parameterized for consistent welds.

Material data sources: ScienceDirect — Plastic welding topics.

5. Design-for-Weld (DFW) — Practical Rules

DFW helps design parts that weld repeatably and reliably. Practical rules include:

- Keep wall thickness near the weld interface uniform

- Provide flash traps to collect excess melt

- Use alignment features for accurate fixture location

- Avoid dissimilar polymer pairings unless specialized adhesive/welding technique available

- Minimize metal inserts across the weld interface

Example DFW diagrams and guidance: request a Dizo Sonics DFW checklist via Contact Us.

6. Process Parameters & Typical Ranges

The following table lists typical parameter ranges as starting points. Final values must be tuned per material and geometry.

| Parameter | Typical Range | Notes |

|---|---|---|

| Platen temperature | 160–350°C | Material dependent; monitor multi-zone uniformity |

| Melt time / soak | 2–25 s | Based on thickness and thermal conductivity |

| Join pressure | 0.2–6 MPa | Servo-controlled; ramp profiles recommended |

| Cooling / hold time | 2–60 s | Depends on material crystallinity & part mass |

| Melt displacement | 0.4–2.5 mm | Measured by displacement sensors |

Parameter optimization often uses Design-of-Experiments (DOE) and capability studies. Dizo Sonics can provide process development and testing support; see our laboratory services via Contact Us.

7. Fixtures, Tooling & Clamping Design

Fixture precision is critical for dimensional accuracy and weld integrity. Consider:

- Rigid frames with low thermal expansion

- Quick-change fixture plates for multi-model production

- Clamping surfaces with low friction coatings

- Integrated sensors in fixture for position & force feedback

Fixtures typically incorporate indexing pins, locator bosses and venting passages to allow trapped air to escape during melt.

8. Quality Assurance & Test Methods

Robust QA prevents field failures. Typical QA measures include:

- Force curve logging for each weld cycle

- Thermal imaging audits during commissioning

- Destructive testing (tensile/pull, shear)

- Non-destructive testing (pressure decay, ultrasonic leakage)

- Statistical process control (SPC) using weld curve features

Standards & references: ISO machine safety and quality frameworks — read primary references at ISO.org and automotive quality standards (IATF 16949).

9. Automation & Industry 4.0 Integration

Modern hot plate welding lines are integrated into factory automation ecosystems: PLC/SCADA for machine control, MES for traceability, and cloud analytics for predictive maintenance. Typical elements:

- Barcode / RFID labeling per part

- Weld data storage per part (temperature, pressure, displacement)

- Cloud dashboards for OEE & quality KPIs

- AI models for anomaly detection on welding curves

Authoritative source on Industry 4.0 manufacturing principles: Industry 4.0 — Wikipedia.

10. Comparative Case Studies

Below are illustrative (anonymized) case summaries showing quantitative benefits after adopting hot plate welding solutions:

10.1 Pallet Manufacturer (Asia)

- Problem: weak runner-to-deck joints and high scrap

- Solution: custom hot plate welding line with servo clamps

- Result: weld strength +40%, scrap −18%, output +1.8x

10.2 Automotive Tier-1 (Europe)

- Problem: leakage on washer tanks and inconsistent cycle times

- Solution: hot plate machine with multi-zone temperature & automated visual QC

- Result: leak rate reduced to near zero, cycle time optimized by 12%

See more engineering case references and machine builds on our project pages: Products and contact us for detailed case studies: Contact.

11. Comparison Matrix: Hot Plate vs Other Welding Methods

This matrix helps procurement and engineering teams select technologies based on product attributes.

| Attribute | Hot Plate | Ultrasonic | Vibration | Infrared |

|---|---|---|---|---|

| Best for | Large, thick, sealed parts | Small precision parts | Large flat PP joins | Cosmetic thin parts |

| Cycle time | Medium | Fast | Medium | Fast |

| Capital cost | Moderate | Low | Moderate | Higher |

| Process complexity | Medium–High | Low–Medium | Medium | Medium |

| Best materials | PP, PE, HDPE, ABS | ABS, PC, small PP | PP | ABS, PC |

Reference reading on ultrasonic welding: Ultrasonic welding — Wikipedia.

12. Procurement Checklist

When evaluating suppliers for hot plate welding machines consider the following:

- Temperature uniformity specification & verification method

- Servo vs pneumatic clamping choice and data logging capability

- Fixture design support and spare parts availability

- Local service & commissioning support

- Reference customers and relevant case studies

- Warranty and training package

Downloadable procurement checklist is available by contacting our engineering team: Contact.

13. Regulatory & Standards References

Relevant standards and references for welding machinery, quality and safety:

- ISO — International Organization for Standardization

- ISO guidance on welding & manufacturing (search for relevant standards)

- IATF 16949 — Automotive quality management

- Plastics Industry Association

Dizo Sonics provides CE/UL documentation and machine safety packages with each machine for audit readiness.

14. FAQs — Quick Answers for Engineers & Buyers

Q: Can hot plate welding join glass-fiber reinforced polymers?

A: Yes, but fiber exposure and localized thermal gradients must be controlled. Fixture and pressure profile adjustments are often required.

Q: What is the expected payback period for a pallet hot plate welding line?

A: Typical ROI is 6–18 months depending on production volume and labor costs — request a project ROI analysis from our sales engineers.

Q: Do you offer on-site testing and sample welding?

A: Yes — use Contact Us to schedule sample trials and parameter development.

15. Further Reading & Authoritative External Links

16. Contact & Next Steps (Strong CTAs)

For project quotes, free weld trials, fixture design assistance and full production line proposals, contact our engineering team.

Email: sales04@nicle.cn • WhatsApp: +86 15358007790

17. Advanced Process Engineering — DOE for Weld Parameter Optimization

For production reliability and short validation cycles, engineers apply Design of Experiments (DOE) to identify robust welding parameter windows. DOE reduces time-to-process-capability and quantifies parameter sensitivities.

Typical DOE Workflow

- Define response metrics: tensile strength, leak pressure, cycle yield.

- Select factors: platen temperature, melt time, weld pressure, melt displacement, cooling time.

- Choose experimental design: fractional factorial or central composite design for non-linear responses.

- Run systematic trials and capture weld curves, pressure profiles, thermocouple data.

- Analyze with ANOVA / regression to build predictive models and identify significant interactions.

- Validate optimized recipe on production tooling and refine with guard-banded parameters for process drift.

Data acquisition is critical: collect per-cycle time-stamped platen temperature zones, displacement encoder traces, and force transducer signals. These are the inputs for quality control gating and machine-learning models for predictive detection of out-of-spec welds.

External reference on DOE methods: Design of experiments — Wikipedia

18. Weld Curve Interpretation & In-Process Signatures

Weld curve analysis provides a real-time fingerprint of each weld. A properly recorded weld curve typically includes stages for pre-press, melt/soak, retract/displacement, joining pressure and cooling hold. Deviations from expected signatures quickly identify process drifts.

Key Curve Features to Monitor

- Heating plateau — stable temperature before retract

- Displacement overshoot — indicates softening beyond target melt

- Force ramp slope — related to part stiffness and fixture alignment

- Cooling pressure decay — indicates possible thermal relaxation or creep

Modern control systems allow real-time alarm setpoints derived from statistical baselines (mean ± 3σ). For more advanced lines, implement auto-hold logic where the machine holds a part until weld curves return into the acceptance band.

See welding data analytics approaches: ScienceDirect — Weld quality analytics

19. Maintenance, Spare Parts & Lifecycle Management

Preventive maintenance ensures long-term stability and reduces unscheduled downtime. Hot plate welding machines include thermal elements, servo motors, linear guides, pressure transducers, PLC components and heater coatings—each requiring planned maintenance.

Recommended Maintenance Schedule

| Interval | Activity | Responsible |

|---|---|---|

| Daily | Clean platen surfaces; visual check of fixtures | Operator |

| Weekly | Check fasteners, lubricate linear guides | Technician |

| Monthly | Calibrate thermocouples; inspect heater elements | Maintenance Engineer |

| Quarterly | Force transducer verification; servo axis backlash check | Service Engineer |

| Yearly | Full preventive maintenance, replace critical wear parts | OEM Service |

Maintain an electronic spare parts list and reorder critical consumables (heating elements, PTFE coatings, sensors) to guarantee Mean Time To Repair (MTTR) targets.

Dizo Sonics offers spare parts kits and service contracts — contact via Contact Us.

20. Commissioning & Factory Acceptance Testing (FAT)

Commissioning is where machine capability meets production reality. A structured FAT ensures the delivered system meets contractual specifications, safety and production targets.

FAT Checklist

- Verify machine specification vs contract (force, temperature uniformity, cycle time).

- Run sample production parts and measure weld strength.

- Validate safety systems (guards, E-stops, interlocks) per CE/IEC standards.

- Test MES/ERP connectivity and data logging.

- Perform operator training and handover of SOPs and maintenance plans.

For remote or overseas installations, agree on witness FAT procedures and digital acceptance metrics before shipping.

21. Procurement & RFP Template for Hot Plate Welding Machines

Use a structured Request for Proposal (RFP) to compare suppliers objectively. Below is a condensed checklist that you can integrate into your procurement RFQ.

Essential RFP Items

- Machine Specification: platen size, temperature zones, maximum clamping force, stroke lengths.

- Control & Traceability: PLC model, HMI, per-cycle data logging, connectivity options (OPC-UA, MQTT).

- Fixtures & Tooling: included fixtures, quick-change capability, tolerance specifications.

- Automation: robot integration points, conveyors, part indexing systems.

- Quality Features: force/temperature feedback, weld curve storage, QA gating.

- Service & Support: warranty, spare parts list, local service partners, training scope.

- Project Delivery: FAT procedures, installation timeline, acceptance criteria.

- Price & Commercial: machine price, tooling cost, shipping, installation, training, spare parts pricing.

For a customizable RFP template and supplier comparison workbook, contact our solutions team: Contact Us.

22. Troubleshooting & Common Problem-Solution Patterns

The following table maps common production issues to engineering remedies.

| Issue | Likely Cause | Corrective Action |

|---|---|---|

| Cold welds / low bond strength | Insufficient melt depth or low platen temp | Increase temperature or melt time; verify thermocouples |

| Excessive flash & part distortion | Over-melt or too high joining pressure | Reduce soak time; adjust pressure ramp; inspect fixture alignment |

| Non-uniform weld appearance | Platen temperature non-uniform; coating issues | Perform thermal mapping; refurbish coating |

| Intermittent reject spikes | Sensors out of calibration | Calibrate displacement and force transducers; review weld curve logs |

| Electrical faults / PLC errors | Wiring or grounding problem | Follow OEM electrical checklist; call certified service |

Logging and analyzing weld curve data is the fastest route to diagnose intermittent issues — most production drifts present as small but consistent changes in force or displacement signatures.

23. Extended FAQs — Engineering & Commercial

Q1: How long does it take to validate a welding process?

A1: For a new geometry and material, full validation (DOE, capability study, FAT) typically takes 2–8 weeks depending on part complexity and tooling readiness.

Q2: Can hot plate welding be used for multi-material assemblies?

A2: Direct welding of dissimilar thermoplastics is generally not feasible; specialized adhesives or intermediate materials are used. In some cases, energy directors or ultrasonic hybrid techniques can join compatible blends.

Q3: What is the expected lifetime of a hot plate heater?

A3: Heater life varies with usage and material abrasion; typical replacement intervals range from 1–4 years for high-volume lines. Coating and proper cleaning extend life.

Q4: Do you provide OEM spare parts globally?

A4: Yes — Dizo Sonics maintains spare parts inventory and service agreements; contact local sales for logistics and pricing.

Q5: How do you handle confidential IP & tooling designs?

A5: We sign NDA agreements and maintain secure project data management policies during tooling design and commissioning.

24. Glossary — Key Terms for Engineers

- Platen

- The heated plate that contacts part surfaces in hot plate welding.

- Soak time

- The duration the platen contacts the parts to achieve desired melt depth.

- Displacement

- Measured movement of parts during joining; used for melt control.

- Force curve

- Recorded pressure/force profile during the weld cycle.

- Melt layer

- The softened polymer thickness that diffuses during joining.

- DOE

- Design of Experiments — systematic trial method to optimize processes.

25. Authoritative External References & Research Links

26. Additional CTAs & Conversion Paths

Use these CTAs on pillar pages and product pages to drive engineering inquiries and sample requests.

Pro tip: place a visible floating WhatsApp CTA on site to capture mobile leads — WhatsApp: +86 15358007790

27. Closing Remarks — How to Proceed

This technical guide provides a structured, engineering-first overview for selecting and deploying hot plate welding machines and associated plastic welding technologies. For hands-on evaluation, Dizo Sonics offers sample welding, DOE support, commissioning, and global service. Start with a part feasibility discussion and we will provide a tailored project plan.

36. Quality Control & Statistical Validation

Plastic welding process validation is not complete without statistical capability analysis. Automotive and medical industries commonly apply CP and CPK for production stability checks.

CP / CPK Definitions

- Cp: Process capability (spread vs tolerance)

- Cpk: Process capability index (spread + centering)

Required benchmarks by tier-1 OEMs:

- Cp ≥ 1.67 for capability check

- Cpk ≥ 1.33 for mass production

Formula reference:

Cp = (USL − LSL) / (6σ)

Cpk = min[(USL − μ) / (3σ), (μ − LSL) / (3σ)]

Learn statistical process control (SPC): Wikipedia: Process Capability Index

37. Sample Weld Traceability Table

| Date | Machine | Material | Melt Temp | Force | Displacement | Result |

|---|---|---|---|---|---|---|

| 2025-02-01 | Hot Plate Line-03 | PP-GF20 | 235°C | 3.8kN | 1.92mm | PASS |

| 2025-02-01 | Ultrasonic-A2 | ABS | N/A | 840N | 0.52mm | PASS |

| 2025-02-01 | Vibration-BX | HDPE | Friction | 6.4kN | 2.65mm | PASS |

Download full traceability template:

38. AI-Enabled Welding Control & Predictive Quality

Dizo Sonics integrates AI-assisted anomaly detection for joining cycles based on force-time, distance-time, and temperature-displacement vectors.

Key AI Monitoring Features

- Weld curve signature learning

- Outlier detection on thermal deviation

- Predictive consumable life (heaters, sonotrodes)

- Cycle-time performance trends

- Anomaly alerts with operator guidance

Reference machine learning concept:

Wikipedia: Anomaly detectionSee industrial welding equipment: Dizo Sonics Products

40. Global Industry Adoption Matrix

Where plastic welding systems are widely used:

| Industry | Applications | Recommended Tech |

|---|---|---|

| Automotive | Bumper beams, ducts, door trim | Hot plate / Ultrasonic / Vibration |

| Logistics | Plastic pallets, bins | Hot plate |

| Medical | Filters, IV components | Ultrasonic |

| Consumer | Electronics casings | Ultrasonic |

| Appliances | Water reservoirs, drums | Hot plate |

Learn more: Dizo Sonics Case Studies

41. Request Engineering Benchmarking

Compare hot plate welding, ultrasonic welding, vibration welding, and high-frequency welding with your real parts and drawings.

Get Free Technical Assessment