DIZO ULTRASONIC TECHNOLOGY

Dizo focuses on cutting-edge ultrasonic technology, specializing in the design and manufacture of intelligent, automated plastic welding systems. We deliver customized ultrasonic welding solutions engineered to meet each client’s unique technical specifications and production needs.

START PLANNING YOUR PROJECT

Customize Your Plastic Welding Machine

As a trusted manufacturer and supplier of plastic welding machines, we deliver high-quality products with competitive advantages and provide custom solutions backed by industry-leading certifications

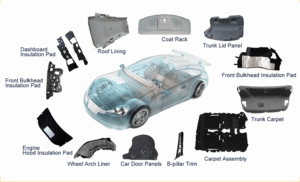

Custom Auto Inner Parts Robotic Ultrasonic Welding Workstation

Ultrasonic welding system delivers rapid, precise, and energy-efficient welding of diverse automotive interior components with advanced thermal, acoustic, and sensor-controlled process management.

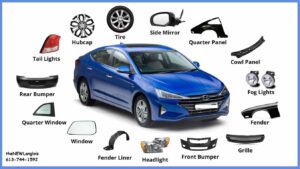

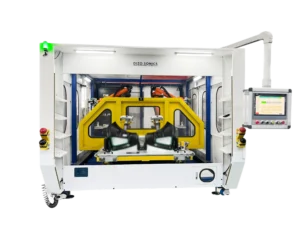

Custom Auto Exterior Parts Multi-head Ultrasonic Welding Machine

Modern multi-head ultrasonic welding delivers ultra-strong, energy-efficient, multi-point, and IoT-controlled precision for complex automotive components, enabling faster, greener, and highly flexible production.

Auto Bumper Ultrasonic Welding & Punching Machine

Dizo Sonics delivers high-precision, eco-friendly ultrasonic welding and punching for automotive bumpers, combining superior strength, flawless accuracy, high-speed production, and smart Industry 4.0 integration.

Auto Tank Hot Plate Welding Machine

Dizo Hot Plate Welding — Faster, Stronger, Greener. Precision plastic joining for next-gen automotive manufacturing.

Auto Lamp Hot Plate Welding Machine

Achieve unmatched welding strength with our hot plate welding machine for car headlights, turn signals, brake lights, taillights, and fog lights.

Auto Door Panel Servo Heat Staking Machine

Auto Door Panel Servo Heat Staking Machine delivers eco-friendly welds with exceptional speed and seamless integration for automotive production.

Custom Auto Heat Staking & Hot Plate Combo Welding Machine

The hybrid hot plate welding and heat staking system delivers precise, energy-efficient, and versatile joining for plastics and metals, enabling faster, greener, and high-quality automotive manufacturing.

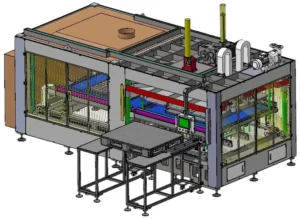

Custom Auto Interior Parts Automatic Ultrasonic Welding Machine

Dizo’s ultrasonic plastic welding machines deliver ultra-fast, precise, and durable thermoplastic bonds for complex automotive components, combining high efficiency and uncompromising quality control.

Servo Plastic Ultrasonic Welder

Combining ultra-precise servo control with high-frequency ultrasonic energy, this machine delivers lightning-fast, stable, and flawless plastic welds for high-end manufacturing.

Pneumatic Plastic Ultrasonic Welder

The pneumatic plastic ultrasonic welding machine uses high-frequency vibrations and controlled pneumatic pressure to precisely fuse thermoplastics, creating strong, durable molecular bonds.

Desktop Ultrasonic Welder

Portable, safe, and customizable desktop ultrasonic welder with intuitive controls, advanced noise reduction, and easy transport for multi-location precision welding.

Handheld Ultrasonic Spot Welder

Lightweight, ergonomic, and rapidly deployable, this ultrasonic spot welder delivers precise, versatile, and consistent bonds across a wide range of materials.

Custom Auto Inner Parts Robotic Ultrasonic Welding Workstation

Dizo’s robotic ultrasonic welding system delivers rapid, precise, and energy-efficient welding of diverse automotive interior components with advanced thermal, acoustic, and sensor-controlled process management.

Vibration Welding Machine

Precision friction welding solutions delivering unmatched strength, faster changeovers, and full customization for the most demanding industries.

Ultrasonic Nozzle Vibration Machine

Efficiently separates hard plastics and small components with optimized discharge, easy operation, and durable ultrasonic components.

Auto Door Panel Servo Heat Staking Machine

The Dizo Auto Door Panel Servo Heat Staking Machine delivers high-strength, airtight, and eco-friendly welds with exceptional speed, energy efficiency, and seamless integration for sustainable, high-volume automotive production.

Automotive

Dizo Sonics delivers fast and efficient welding solutions for a wide range of automotive components, including bumpers, lights, dashboards, door panels, center consoles, fuel tanks, coolant reservoirs, and wheel covers.

Home Appliances

Medical Devices

Toys

Packaging

What We Do

Before developing your custom plastic welding solution, we offer full support, including technical consultations, sample testing, quality inspections, and tailored solution design. Our team works closely with you to ensure smooth implementation and optimal performance

Lifetime support & one-Year Warranty

Benefit from unlimited technical support, a comprehensive one-year warranty, and 24/7 engineer availability with guaranteed response within 8 hours.

Free Consultation & Expert Guidance

Get expert guidance on model selection, along with complimentary design support and on-site technical assistance.

Transparent ManufacturingProcess

Customers can monitor every stage of production in real time.

Customized Technical Training

Customized programs designed to meet user requirements, with continuous support for product upgrades.

Detailed Inspection Documentation

Providing thorough inspection standards and verified results directly to your technical teams.

About Dizo Sonics

Dizo Sonics, headquartered in Wuxi, China, with a presence in Shanghai’s business district, is a professional manufacturer and supplier of plastic welding machines. With a team of 102 employees, including 21 engineers, and partnerships with two leading universities, we maintain an annual production capacity of 3,000 machines and 10,000 sets of accessories.

Why Choose Dizo?

With 15 years of ultrasonic expertise and a commitment to innovative, eco-friendly solutions, we are your trusted partner in advancing technology.

Our Mission: Technology Leadership

Dizo advances manufacturing excellence through innovative R&D in plastic welding technology, offering sustainable, eco-friendly solutions that minimize waste and energy use while ensuring consistent quality through a global service network. By integrating technical expertise with operational excellence, we forge lasting partnerships with our customers.

Your Trusted Welding Partner

With more than 16 years of experience in plastic welding, Dizo Ultrasonic provides expert guidance, transparent communication, and reliable solutions. By partnering with industry leaders, we integrate advanced welding technology with intelligent industrial solutions to enhance efficiency, competitiveness, and sustainable manufacturing.

Reliability, safety and a quick service

At Dizo, we provide personalized support to keep your production running seamlessly. From start-up guidance and process optimization to user training, maintenance, and fast after-sales service—including spare parts, repairs, and modifications—we ensure your operations remain efficient. For added peace of mind, rental or loaner machines are available to prevent any downtime.

Latest News & Article

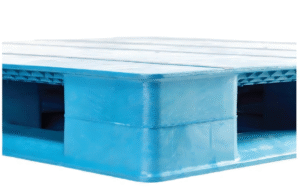

Post Views: 55 🏭 How Plastic Pallet Welding Equipment Reduces Injection Machine Tonnage and Initial Investment For plastic pallet manufacturers, high injection molding machine tonnage

Our Reviews