Hot Plate Welding Machine vs Ultrasonic Welding Machine vs Vibration Welding Machine vs High Frequency Welding Machine — Differences, Similarities and Industrial Applications

A practical, in-depth guide for engineers, purchasing managers and production planners comparing hot plate welding machine, ultrasonic welding machine, vibration welding machine and high frequency welding machine. Includes tooling considerations, material compatibility, cycle time, automation, quality control and recommended suppliers.

Executive summary

This guide compares four major plastic welding technologies: the hot plate welding machine, the ultrasonic welding machine, the vibration welding machine (also called linear vibration welding), and the high frequency welding machine (radio frequency welding). Each process has strengths and limits. The hot plate welding machine excels at large-area joins and heavy-duty parts such as plastic pallets and tanks. The ultrasonic welding machine is fast and precise for small-to-medium components like electronics and automotive interior parts. The vibration welding machine is ideal for complex geometries and large parts where controlled relative motion creates friction heat. The high frequency welding machine (RF welding) is best for materials with polar molecular structure (PVC, TPU) and for flexible films, textiles and coated fabrics.

Throughout this article we will use the keywords hot plate welding machine, ultrasonic welding machine, vibration welding machine and high frequency welding machine repeatedly and naturally to support SEO and help search engines associate this page with queries about plastic welding technologies.

Table of contents

- Overview of the four welding technologies

- How each process works (principles)

- Material compatibility & selection

- Typical applications and industries

- Process parameters and tooling

- Cycle time, throughput and cost comparison

- Automation & integration (robots, PLCs, vision)

- Quality control, testing and standards

- Advantages and disadvantages summary

- Case studies and supplier recommendations

- How to choose the right machine for your factory

- References and further reading (external links)

1. Overview of the four welding technologies

Hot plate welding machine, ultrasonic welding machine, vibration welding machine, and high frequency welding machine are common joining methods used across plastics manufacturing. They differ in heat generation method, cycle dynamics, tooling, and ideal part geometry.

Hot Plate Welding Machine — quick intro

A hot plate welding machine uses a heated platen (hot plate) to soften the mating surfaces. After melting, the hot plate is removed and the two parts are pressed together to form a fused joint. This method is suitable for large-area bonds, thick sections and assemblies such as plastic pallets, tanks and large housings.

Ultrasonic Welding Machine — quick intro

An ultrasonic welding machine uses high-frequency (typically 20-40 kHz) mechanical vibrations transmitted through a horn (sonotrode) into the joint. The vibrations create frictional heating in a small interface area, melting the plastic and forming a weld—commonly used for small to medium parts and high-speed production.

Vibration Welding Machine — quick intro

A vibration welding machine, often called linear vibration welding or orbital welding, creates heat by rubbing two parts against each other under pressure with controlled relative motion (linear or orbital). It is valuable for large or asymmetric parts where ultrasonic or hot plate may be impractical.

High Frequency Welding Machine — quick intro

A high frequency welding machine (RF welding, dielectric welding) uses electromagnetic energy (typically 13.56 or 27.12 MHz) to excite polar molecules in plastics such as PVC and TPU. This produces heat internally for film sealing and flexible materials bonding (e.g., medical bags, inflatable products, coated textiles).

2. How each process works (principles)

Hot plate welding machine — principle

Steps: (1) Alignment and clamping of two parts, (2) bring hot plate into contact and heat both mating surfaces, (3) retract hot plate, (4) bring parts together under controlled pressure, (5) hold during cooling. The hot plate temperature, contact time, and pressure determine weld quality. The hot plate welding machine relies on conductive thermal transfer from the platen into the parts.

Ultrasonic welding machine — principle

The ultrasonic welding machine converts electrical energy to high-frequency mechanical vibrations via an ultrasonic transducer and booster. A horn concentrates the vibrations to the joint area. Frictional heating and intermolecular movement at the interface melt the plastic locally. Typical cycle includes: (1) part placement, (2) horn descent, (3) energy application for a set time/energy, (4) hold under pressure until solidification.

Vibration welding machine — principle

In vibration welding, heat is generated by macroscopic sliding at the joint interface. Parameters include vibration amplitude, frequency (often low frequency compared to ultrasonic), pressure, and time. Because heating is distributed broadly along the interface, it is useful for thick or irregular joints. The vibration welding machine often features fixtures that allow for consistent reciprocating motion.

High frequency welding machine — principle

The high frequency welding machine applies an alternating electromagnetic field between electrodes across the parts. Polar molecules (e.g., PVC) oscillate and generate heat internally. Welding occurs for thin films and coated fabrics; sealing is achieved quickly and cleanly. Non-polar plastics (PE, PP) are not responsive to RF heating unless special additives are used.

3. Material compatibility & selection

One of the most important criteria when choosing between a hot plate welding machine, ultrasonic welding machine, vibration welding machine or high frequency welding machine is the base polymer.

Materials typically welded by ultrasonic welding machine

The ultrasonic welding machine excels with amorphous and semi-crystalline thermoplastics such as ABS, PC, PMMA, PA (nylon), and some PP blends. It is highly effective for small, precise joins where localized heat is preferred. See a general compatibility list at Wikipedia: Plastic welding - Wikipedia.

Materials typically welded by hot plate welding machine

The hot plate welding machine is versatile for PP, PE, HDPE, reinforced plastics and other thermoplastics used in thick sections. Hot plate can handle large parts and dissimilar thicknesses. For heavy-duty applications (e.g., plastic pallets), hot plate welding is often chosen for its deep melt and strength.

Materials typically welded by vibration welding machine

The vibration welding machine works well with semi-crystalline plastics such as PP and PE. Vibration welding can join larger and more complex geometries where ultrasonic energy would not penetrate evenly.

Materials for high frequency welding machine

The high frequency welding machine is effective for polar materials such as PVC, polyurethane (PU/TPU), and some coated textiles. It is the go-to choice for medical bags, inflatable products and laminated materials used in packaging and textiles.

Notes on additives, fillers and reinforcement

Filled or glass-fiber reinforced plastics can alter heating characteristics. Metals, conductive fillers, or high pigment loads may reduce efficacy of ultrasonic welding or RF welding. Consultation with machine manufacturers about material batches is recommended. Reference: ScienceDirect - Plastic Welding.

4. Typical applications and industries

Each welding machine has typical use-cases:

Hot plate welding machine applications

- Large plastic pallets, containers and crates

- Fuel and fluid tanks (automotive and industrial)

- Large housings and furniture-grade plastic joins

- Parts that require full-surface fusion and high joint strength

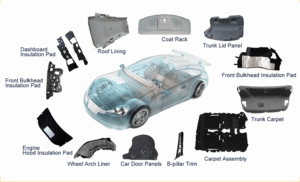

Ultrasonic welding machine applications

- Automotive interior components, instrument panels, sensor housings

- Consumer electronics enclosures, connectors

- Medical device assemblies (disposable components)

- Packaging closure and precision assemblies

Vibration welding machine applications

- Large assemblies with complex geometries (e.g., fuel tanks, large housings)

- Parts with extensive ribbing or uneven surfaces

- Assemblies where tight dimensional control along one axis is possible

High frequency welding machine applications

- Flexible films, tarpaulins, coated fabrics

- Medical bags, IV bags and sealed pouches

- Inflatable products and consumer packaging

For examples of industrial implementations, review resources from Plastics Today: Plasticstoday.com.

5. Process parameters and tooling

Understanding process variables and tooling is essential for production success.

Hot plate welding machine — tooling and parameters

Key parameters: hot plate temperature, plunge time, retraction speed, forge force, cooling time. Tools include large-area heating platens, fixtures for part alignment, and often multi-station machines for high throughput. Hot plate tooling must be machined flat, often with non-stick coatings.

Ultrasonic welding machine — tooling and parameters

Key parameters: frequency (20/30/40 kHz), amplitude, weld time, weld energy, clamp force. The sonotrode (horn) shape is central to energy distribution. Booster and transducer selection affect available amplitude. Ultrasonic tooling (horn and nest) should be designed to avoid resonance and to focus energy at the joint. Manufacturers such as Dizo Ultrasonic supply custom horn designs — see product pages for example systems: Dizo Products.

Vibration welding machine — tooling and parameters

Key parameters: vibration amplitude, frequency, oscillation distance, pressure, welding time. Tooling involves fixtures that constrain parts while permitting relative movement. The tooling must be robust due to reciprocating loads.

High frequency welding machine — tooling and parameters

Key parameters: RF power, electrode design, pressure, dwell time, cooling. Electrodes can be patterned for seam shape. Insulation and safety for high-voltage components are important. For medical and packaging, tooling must meet hygiene standards.

6. Cycle time, throughput and cost comparison

Cycle time and throughput directly affect ROI. Below is a general comparison (actual numbers depend on part geometry and automation):

| Technology | Typical Cycle Time | Throughput | Equipment Cost (typical) |

|---|---|---|---|

| Hot plate welding machine | 30s – 300s (large parts) | Low to Medium | Medium to High |

| Ultrasonic welding machine | 0.5s – 5s | High | Low to Medium |

| Vibration welding machine | 10s – 60s | Medium | Medium |

| High frequency welding machine | 1s – 10s | High (films) | Medium |

Note: A single ultrasonic welding machine can achieve very high cycle rates for small parts which reduces labor and footprint. A hot plate welding machine is slower but often the only practical method for very large sections.

7. Automation & integration (robots, PLCs, vision)

All four technologies can be integrated into automated cells. Typical automation elements include part feeding, pick-and-place robots, rotary index tables, PLC control, and vision systems for presence/position verification.

Robotic integration with ultrasonic welding machine

The ultrasonic welding machine integrates well with robotic arms for flexible placement and multi-station operations. Robotic ultrasonic cells are standard in electronics and automotive plants. Vendors often supply robotic turn-key cells; see industrial automation references at Automation.com.

Automation with hot plate welding machine

Hot plate welding is commonly semi-automatic to fully automated in pallet/tank production lines. Automation reduces cycle time by overlapping heating and cooling steps (multi-station approach).

Integration with vibration welding machine

Vibration welding machines are often integrated with conveyors and indexing tables for medium-sized production. The reciprocating motion requires robust fixturing and force monitoring controlled by PLC.

Integration with high frequency welding machine

High frequency welding is integrated into roll-to-roll systems for films or into automated pouch-making machinery. Continuous sealing lines require tension control and edge guiding systems.

8. Quality control, testing and standards

Quality for all welding machines is ensured through process control, non-destructive testing (NDT), mechanical testing and visual inspection.

Quality metrics for ultrasonic welding machine

- Weld strength (pull test, peel test)

- Weld flash and appearance

- Energy per weld (joules)

- Cross-sectional inspection for fusion

Testing for hot plate welding machine

- Drop tests for pallets, burst tests for tanks

- Dimensional verification and flatness

- Hydrostatic tests for fluid-containing parts

Standards and certifications

Manufacturers and buyers should consider ISO standards and industry norms. For medical packaging, refer to ISO 11607; for automotive assemblies, OEM-specific standards apply. External references: ISO.

9. Advantages and disadvantages summary

Hot plate welding machine — advantages & disadvantages

Advantages: large area fusion, strong joints, suitable for thick sections and dissimilar wall thicknesses. Disadvantages: long cycle time, large footprint, energy for platen heating.

Ultrasonic welding machine — advantages & disadvantages

Advantages: very fast, low energy per weld, precise localized heating, easy automation. Disadvantages: limited to certain geometries and part sizes, tooling design can be complex.

Vibration welding machine — advantages & disadvantages

Advantages: handles large, irregular parts; broad interface heating. Disadvantages: oscillating motion may produce flash, tooling must be robust.

High frequency welding machine — advantages & disadvantages

Advantages: ideal for films and polar materials, continuous sealing possible. Disadvantages: limited to RF-responsive materials (PVC/TPU), safety/regulatory considerations for high-voltage systems.

10. Case studies and supplier recommendations

Below are representative use cases and supplier suggestions. This section references reputable sources and provides internal product links.

Case study: hot plate welding machine for plastic pallet production

Large plastic pallet manufacturers often switch from single-shot injection molding to a two-step process (mold top and bottom, then join using a hot plate welding machine) to reduce injection machine tonnage and capital costs. For high-volume pallet welding systems, see specialized product examples: Hot Plate Plastic Pallet Welding Machine — Dizo.

Case study: ultrasonic welding machine in automotive interiors

Ultrasonic welding is widely used to assemble instrument panels and air duct parts with high repeatability. For fast cycle production, consider 20 kHz or 30 kHz ultrasonic welding machine units with automated feeders.

Recommended suppliers and resources

- Dizo Ultrasonic Technology — product portfolio (internal link)

- Branson (Emerson)

- Herrmann Ultrasonics

- PlasticsToday — industry articles

11. How to choose the right machine for your factory

Decision factors:

- Part size and geometry (small precise vs. large area)

- Material type (polar vs non-polar; amorphous vs semi-crystalline)

- Production rate requirements

- Available floor space and automation plan

- Budget for equipment and tooling

If your primary products are small, high-volume parts (connectors, electronics housings), an ultrasonic welding machine will often deliver the best ROI. If you manufacture large pallets or tanks, a hot plate welding machine or vibration welding machine should be considered. For films and coated fabrics, a high frequency welding machine is usually the preferred choice.

For assistance choosing the right solution, request a free consultation and sample testing from a supplier like Dizo: Contact Dizo Ultrasonic.

12. Practical recommendations and best practices

- Prototype and sample testing: Always run sample welding tests with actual production material and tooling before committing to a full production line.

- Design for welding: Optimize part geometry and joint design for the chosen welding method (energy directors for ultrasonic, planned flash zones for vibration/hot plate).

- Tooling maintenance: Keep sonotrodes, horns, hot plates and electrodes clean and within spec. Replace worn tooling promptly.

- Process monitoring: Use energy, time, force and temperature logs for traceability and quality control.

- Operator training: Skilled technicians reduce setup time and scrap.

13. Environmental & safety considerations

Ultrasonic, vibration and hot plate welding eliminate adhesives and solvents, producing cleaner processes and fewer volatile organic compounds (VOCs). High frequency welding requires high-voltage safety management and shielding. Flooring, ventilation and operator PPE should be chosen per local regulations. For environment-related guidance see: EPA and local standards.

14. Summary & final comparison

The following table summarizes strengths and typical use-cases:

| Technology | Best For | Strengths | Limitations |

|---|---|---|---|

| Hot plate welding machine | Large parts, pallets, tanks | Deep melt, strong joints | Slow, large footprint |

| Ultrasonic welding machine | Small/medium precise parts | Very fast, low energy, easy automation | Geometry/material limits |

| Vibration welding machine | Large irregular parts | Handles complex shapes | Flash control, tooling wear |

| High frequency welding machine | Films, PVC/TPU products | Continuous sealing, films | Material-specific |

Choosing between a hot plate welding machine, ultrasonic welding machine, vibration welding machine and high frequency welding machine depends on your parts, materials and production goals. Engage with suppliers early, run sample tests and plan tooling and automation for the best long-term ROI.

15. Useful external resources & references

16. Contact & next steps

If you are evaluating welding technologies and want sample tests, ROI calculations, or a factory layout consultation, contact a solutions provider. For example, request a demo or consultation: Request a Quote — Dizo Ultrasonic.