Plastic Welding Machine in the Automotive Industry — Complete Technical & Application Guide

In-depth coverage of ultrasonic welding, hot plate welding, vibration welding, infrared, laser-assisted, hybrid systems, tooling, QC, and real-world automotive applications including EV components, fuel & washer tanks, bumpers, dashboards, HVAC ducts and plastic pallets.

📲 WhatsApp: +86 15358007790 — Request Sample Weld / QuoteOverview — Why Plastic Welding Machines Matter in Automotive Manufacturing

Plastic components are central to modern automotive design. Lightweight thermoplastics such as PP, HDPE, PA, ABS, PC/ABS and TPO are used in exterior and interior components, fluid handling systems, EV battery housings and thermal management parts. For reliable, repeatable, high-volume production, automotive manufacturers use a variety of plastic welding machines including ultrasonic welding machines, hot plate welding machines, vibration welding machines, and infrared/laser welding systems.

This guide explains how each welding method is used on a part-level basis, shows typical parameters, tests and validations (leak tests, burst tests, 3m drop tests for pallets), and provides tooling & automation tips. The guide intentionally integrates a broad set of keywords and long-tail phrases (e.g., plastic welding machine, welding plastic machine, plastic weld machine, hot plastic welding machine, plastic pipe welding machine) so it can serve as a pillar page for industrial SEO and lead capture for suppliers and Tier-1 manufacturers.

Plastics & Material Selection for Automotive Welding

Choosing the right materials and understanding their melt behavior is the first step to selecting the correct welding process. Common automotive thermoplastics and recommended welding approaches:

| Material | Common Automotive Parts | Recommended Welding Methods |

|---|---|---|

| PP (Polypropylene) | Bumpers, Ducts, Trim, Pallets | Hot Plate, Vibration, Ultrasonic (thin walls) |

| HDPE (High-Density Polyethylene) | Fuel Tanks, Washer Tanks, Pallets | Hot Plate, Infrared (in selected cases) |

| PA / Nylon (PA6, PA66) | Intake Manifolds, Engine Bay Components | Vibration, Hot Plate, IR |

| ABS, PC-ABS | Dashboards, Interior Trim, Housings | Ultrasonic, Vibration |

| PC (Polycarbonate) | Optical Housings, Headlamp parts | Ultrasonic (careful), Laser Welding |

| TPO / TPE | Bumper skins, Sealing components | Hot Plate, Vibration |

Material factors affecting weldability: crystallinity (semi-crystalline vs amorphous), fillers (glass fiber, talc), pigments, mold release agents, wall thickness and part geometry. For accurate process selection and parameter development, always run sample weld tests and material compatibility checks.

Welding Technologies — What Machines Are Available?

This section summarizes the core welding technologies used in automotive manufacturing, and when to apply each one.

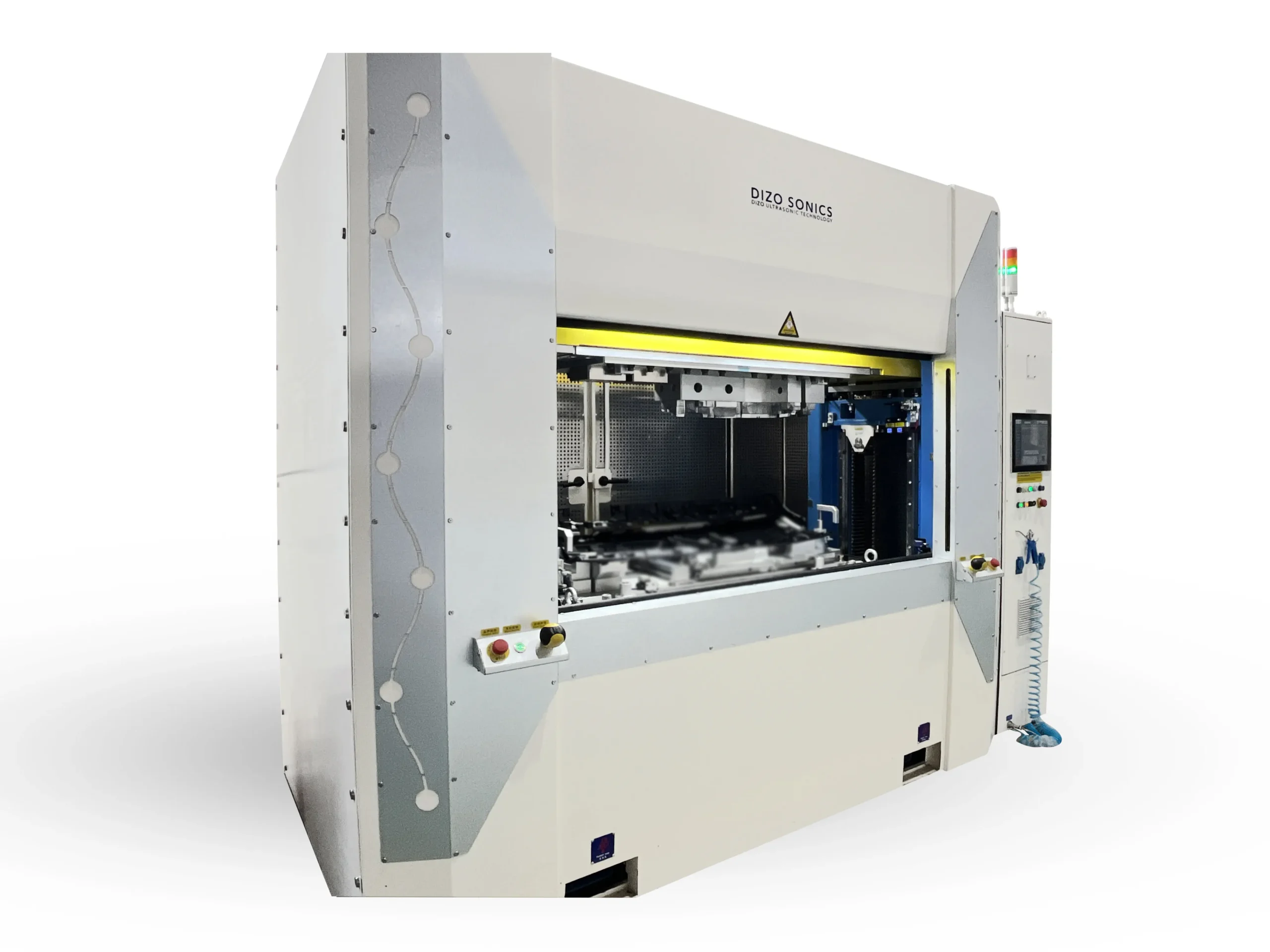

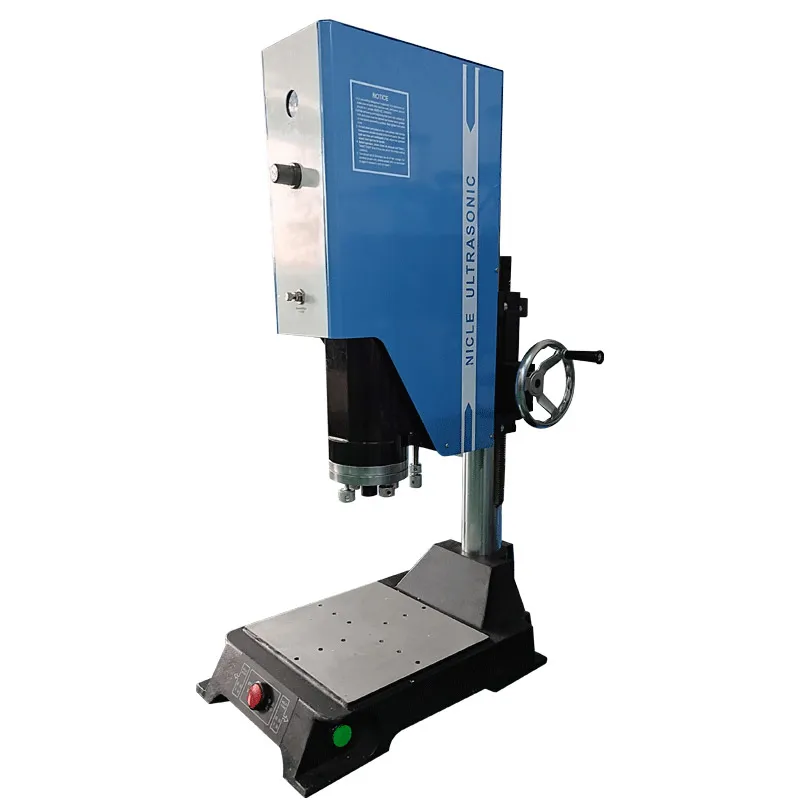

Ultrasonic Welding Machine

Uses high-frequency mechanical vibration (typ. 15–40 kHz) transmitted through a sonotrode to melt thermoplastic interfaces locally. Ideal for clips, connectors, small housings, and high-cycle automated operations.

Hot Plate Welding Machine (Contact Heating)

Uses a heated platen to melt mating flange surfaces of large parts. Preferred for thick-walled parts like fuel tanks, washer tanks, large pallets, and structural housings.

Vibration Welding Machine (Linear / Orbital)

Creates frictional heat through controlled relative motion; excellent for ribbed or complex geometries such as intake manifolds and HVAC ducts.

Infrared Welding & Laser Welding

Non-contact heating using IR radiation or lasers. Best for particle-sensitive parts (EV battery components), optical housings, and minimal flash applications.

Spin Welding & Hybrid Systems

Spin welding is used for circular profiles; hybrid systems (IR preheat + hot plate; ultrasonic spot + hot plate) are increasingly common to solve mixed geometry & aesthetic requirements.

Component-by-Component Welding Guide (Exterior, Interior, Fluids, EV)

This practical reference matches common automotive parts to the recommended welding method and describes typical tests and acceptance criteria.

Exterior Components

- Bumpers & bumper brackets: PP/TPO materials; ultrasonic for clip/joint features, hot plate for heavy structural joins. Tests: impact & paint adhesion.

- Side mirror shells, door handles: typically injection-molded ABS/PC blends; ultrasonic or laser for low-heat assembly to preserve finish.

- Lighting housings & bezels: PC/PC-ABS; laser welding or ultrasonic spot welding for optical clarity.

Interior Components

- Dashboards & instrument clusters: Vibration welding for large ribs; ultrasonic for smaller clips and attachments. Tests: NVH, thermal aging.

- Center consoles & gloveboxes: Ultrasonic and vibration approaches depending on geometry & panel thickness.

Fluid Handling Components

- Fuel tanks (HDPE): Hot plate welding is the industry standard for large molded fuel tanks; helium leak testing and permeation tests are required.

- Washer & coolant reservoirs: Hot plate or IR depending on wall thickness; pressure decay or bubble immersion testing typical.

HVAC & Intake Manifolds

- Intake manifolds: Vibration welding or hot plate depending on thickness; NVH & pressure testing essential.

- Air ducts & resonators: Vibration or ultrasonic for clip inserts.

EV Components

- Battery cooling plates & thermal channels: Hot plate or IR to ensure leak-free liquid channels; material compatibility and flame-retardant grades must be considered.

- Charging connector housings: Ultrasonic welding for integrated clips & inserts with high-precision requirements.

Ultrasonic Welding — Deep Dive (Applications, Parameters, Tooling)

Ultrasonic welding is ubiquitous in automotive assembly for its speed, small footprint, and repeatability. It is often chosen for high-throughput operations where cycle time and part aesthetics matter. Below we present in-depth guidance on ultrasonic technology, process optimization, tooling, common defects, and QC.

System Components & How They Work

A typical ultrasonic welding system includes: generator, transducer, booster, sonotrode (horn), fixture/anvil, and the control module. The generator converts mains power into high-frequency AC; the transducer converts electrical energy to mechanical vibration; the booster adjusts amplitude and force; and the sonotrode contacts the part, delivering the vibrational energy.

Energy Directors & Part Design for Ultrasonic

For semi-crystalline thermoplastics like polypropylene (PP), an energy director (triangular ridge) is commonly molded on one mating surface to concentrate vibration energy and initiate controlled melting. Design guidelines:

- Energy director height: 0.2–0.6 mm for thin walls; larger for thicker parts.

- Angle: 60° triangular ribs are common but geometry should be tuned based on total wall thickness and application.

- Flat land width: keep a small flat zone next to the energy director to find a balance between flash control and weld initiation.

Typical Ultrasonic Weld Parameters (Starting Points)

Note—parameters depend on part geometry, material, and tooling:

- Frequency: 15 kHz (heavy-duty) / 20 kHz (standard) / 35–40 kHz (precision, small features)

- Amplitude: 20–60 μm (micro-meters)

- Pressure: 50–400 N (varies widely with part size)

- Weld time / energy: energy-limited or time-limited approaches are used; typical weld times 0.2–3 seconds for clips & connectors

- Hold time: 0.1–0.8 seconds to let the joint solidify under pressure

Fixture & Sonotrode Design

Custom sonotrode design is critical to distribute amplitude evenly and minimize flash. Tips:

- Match sonotrode contact area to feature geometry

- Use textured or patterned sonotrode faces to improve grip on low-friction materials

- Optimize horn length & taper for amplitude management

- Choose durable materials (titanium for high-duty cycles; aluminum for lighter duty)

Ultrasonic Welding Use Cases in Automotive (Detailed)

Common ultrasonic applications:

- Connector housings & terminal cages — robust electrical connections require secure, repeated welds. Ultrasonic welding provides precise energy control to avoid damage to terminals and offers minimal heat spread to maintain dielectric properties.

- Bumper clip & bracket assemblies — fast automated insertion and ultrasonic spot welding allow high output stations on the bumper assembly line.

- Switch assemblies & keypads — low-temperature welds protect delicate overlays and backlit films.

- Lighting internal mounts — ultrasonic spot welds secure small mounting features without distorting optics.

Quality Control for Ultrasonic Welds

Common QC measures:

- Destructive tests: tensile, shear, peel tests per internal acceptance criteria

- Non-destructive: vision inspection for flash and alignment, ultrasonic NDE for internal voids where applicable

- SPC: monitor energy (J), amplitude (μm), weld time (ms), and hold time to detect drift in process

- Parameter control: store profiles per SKU in PLC & tag parts to specific profiles via barcode/RFID

Troubleshooting Ultrasonic Weld Issues

- Insufficient weld strength — check sonotrode contact, increase energy, check for contamination

- Excessive flash — reduce amplitude / energy or increase clamping precision / flash traps

- Cracking or delamination — verify material compatibility; consider vibration or hot plate if ultrasonic unsuitable

Internal link: Ultrasonic Welding Machines — Product Page

Keyword Integration (Ultrasonic)

ultrasonic welding machine, ultrasonic plastic welding machine, automotive ultrasonic welding, ultrasonic welding for connectors, ultrasonic welding parameters automotive, ultrasonic welding energy, ultrasonic spot welding car parts, ultrasonic welding machine manufacturer.

Hot Plate Welding — In-Depth (Large Parts, Tanks, Pallets)

Hot plate welding is preferred for large, thick-walled parts that require deep melt and high structural strength — common uses include fuel tanks, washer tanks, EV coolant reservoirs, large pallet components, and heavy bumper assemblies.

How Hot Plate Welding Works — Step-by-step

- Approach: Align and clamp both parts close to hot platen without contact.

- Contact & heating: Lower parts onto heated platen to melt the contact face.

- Decompression (optional): A short separation may redistribute the melt layer.

- Forge: Press parts together with controlled pressure; flash is formed and expelled into traps.

- Cooling & hold: Product is held under pressure until weld solidifies to desired handling strength.

Hot Plate Machine Components

- Heated platen(s) — sometimes multi-zone with thermocouple feedback

- Actuators & servo drives — control approach & forge movement

- Tooling with alignment features & flash traps

- Safety enclosures & interlocks

Design Considerations for Hot Plate Welds

- Flange width — ensure adequate width for melt and flash handling

- Wall thickness consistency — reduce localized overheating and warpage

- Plate coatings — PTFE or specialized coatings reduce sticking and maintenance

- Zoned heating — useful for varying wall thickness across large parts

Parameter Examples (Illustrative)

Example for PP tank halves (Note: validate on real parts):

- Platen temperature: 200–240°C (material & pigment dependent)

- Heating time: 15–120 seconds depending on thickness

- Forge pressure: 0.2–2 MPa

- Cooling hold time: until handling strength achieved; may be 30–120 seconds

Testing & Validation

Hot plate welded tanks must pass leak tests, often helium mass spectrometry for fuel system parts, and mechanical strength tests. For logistics components (plastic pallets), a 3m drop test is common to validate dynamic fracture resistance.

Case Example — Plastic Pallet Hot Plate Welding

Problem: Weld both the top and bottom deck plates of an HDPE pallet with internal rib structures and pass a 3m drop test while minimizing cycle time and rework.

Solution: Custom zoned hot plate tooling with quick-clamp system, optimized heating profiles per zone, and flash traps that automatically collect and extract melted flash. Result: 95% first-pass yield, throughput 12 pallets / hour (example).

Keyword Integration (Hot Plate)

hot plate welding machine, hot plastic welding machine, hot plate tank welding, hotplate welding pallet, hot plate plastic welding machine manufacturer, hot plate welding parameters.

Vibration Welding — Deep Dive (Intake Manifolds, Ducts, Large Housings)

Vibration welding (linear, orbital, angular) is designed for large or ribbed geometries and produces deep penetration welds with strong mechanical properties. It is often used in engine intake manifolds, HVAC plenums, and other assemblies where long seams or irregular mating surfaces exist.

Types & Motion Profiles

- Linear vibration — reciprocating linear motion, common for long seams.

- Orbital vibration — small circular motion, good for irregular seams and smaller footprints.

- Angular vibration — small angular oscillations for specialized part geometries.

Typical Parameters

| Parameter | Typical Range |

|---|---|

| Amplitude | 0.5–3 mm |

| Frequency | 50–200 Hz |

| Pressure | 0.5–5 MPa |

| Weld time | 5–60 seconds |

Design & Fixturing Recommendations

- Balance mass to avoid unwanted inertial effects

- Use robust locating features and clamps to prevent micro-motion outside the weld interface

- Provide sacrificial flash channels & traps for molten material

Keyword Integration (Vibration)

vibration welding machine, linear vibration welding automotive, orbital welding intake manifold, vibration weld parameters, automotive vibration welding supplier.

Infrared & Laser Welding — Contactless Precision

Infrared & laser welding are contactless heating methods used for applications where surface quality, particle-free process and minimal flash are critical — for example in EV battery housings, optical components, and sensor enclosures.

Infrared Welding Tips

- Surface emissivity and color affect heating uniformity

- Use clear process windows and shield sensitive components during heating

- Combine with hot plate or ultrasonic spot to handle mixed geometry

Laser Welding for Plastics

Through-transmission laser welding uses a laser wavelength transmitted through the top part and absorbed by the bottom part (or an absorptive interlayer) — enabling narrow, strong welds with minimal flash and high aesthetics (ideal for visible exterior parts).

Keyword Integration (IR / Laser)

infrared welding automotive, laser plastic welding, IR welding EV coolant tank, laser through-transmission welding automotive, contactless plastic welding.

Design for Welding — Practical Guidelines for Automotive Engineers

Design for Welding (DFW) reduces iteration cycles and improves yield. Below is a consolidated checklist and examples for designers working on automotive plastic assemblies.

Top DFW Principles

- Use energy directors for ultrasonic joints (size depends on thickness and polymer)

- Maintain consistent wall thickness around weld area

- Design alignment features — dowels, bosses, and anti-rotation tabs

- Consider flash handling — include flash traps or aesthetic masking zones

- Think about serviceability — integrate access panels or weldable plugs where required

Examples

Example A — Bumper bracket attachment: include flat boss and localized energy director for consistent ultrasonic spot welding.

Example B — Fuel tank flange: increase flange width to 10–20 mm with rounded edges and integrate flash trap cavities to collect excess melt during hot plate joining.

Keyword Integration (Design)

design for welding plastic, energy director automotive, weld flange design, DFW plastic parts.

Tooling, Fixtures & Sonotrode / Horn Design

Tooling and horn/sonotrode design are as important as the machine selection. Proper tooling ensures repeatable welding, reduces flash, and keeps cycle times optimal.

Sáonotrode (Horn) Design Tips

- Choose material for longevity — titanium for heavy duty, aluminum for lower duty

- Shape to match contact geometry & amplitude distribution

- Use surface texturing or knurling when gentle grip is needed on slippery polymers

- Plan for reconditioning and scheduled replacement

Fixture Essentials

- Ensure minimal compliance in fixture to prevent vibrational losses

- Provide easy access for inspection and cleaning

- Integrate quick-change pallets for multi-model production

Keyword Integration (Tooling)

sonotrode design, horn design ultrasonic, hot plate tooling, vibration fixture design, plastic welding fixture supplier.

Quality Control & Testing — Ensuring Automotive-Grade Welds

Automotive products require documented validation and routine QC. Below is a consolidated set of tests and QC practices.

Destructive Tests

- Tensile/Shear/Peel tests per internal or ISO/ASTM standards

- Fatigue testing for moving parts

- Impact & drop tests (e.g. 3m drop for logistics pallets)

Leak & Seal Tests

- Pressure decay

- Bubble immersion

- Helium mass spectrometer for high-sensitivity leak detection (fuel tanks)

Non-Destructive & Inspection

- Ultrasonic NDE for internal voids

- CT/X-ray for complex internal structures

- Machine vision for flash, alignment & cosmetic acceptance

Statistical Process Control

Track key parameters: energy (J), weld time (ms), amplitude (μm), forge pressure. Use SPC charts and maintain Cpk thresholds for process capability.

Keyword Integration (QC)

welding quality test, helium leak test plastic tank, tensile test weld joint, pallet 3m drop test, welding process validation.

Automation & Industry 4.0 — Smart Welding Lines for Automotive Plants

Modern welding lines are integrated with robots, MES, vision systems and cloud analytics. The ROI of automation is significant for high-volume lines, increasing throughput while reducing labor and variability.

Key Automation Components

- 6-axis robots or gantry systems for part handling

- Vision alignment for sub-mm accuracy

- Automatic tool changers & quick-pallet systems

- OPC-UA / MQTT connectivity for MES integration

- Cloud dashboards for KPI & predictive maintenance

Data Points to Capture

- Weld energy and cycle times

- Operator & shift data

- Reject counts & root cause tagging

- Tool life & maintenance events

Keyword Integration (Automation)

robotic welding cell, ultrasonic welding automation, welding MES integration, predictive maintenance welding, welding line automation automotive.

Comprehensive Case Studies — Real Automotive & EV Projects

Below are expanded case studies showing problem statements, engineering solutions, process parameters, and results. These are illustrative; replace with your real project data for best marketing effect.

Case Study A — EV Battery Cooling Plate & Reservoir (Hot Plate + IR Hybrid)

Challenge: Manufacture a leak-free PP cooling reservoir with integrated micro-channels for battery thermal management. Aesthetic surfaces and internal sensor glands required minimal contamination and no rough internal flash.

Solution: IR preheat to soften thin-walled channel surfaces followed by hot plate join for flange integrity. Use PTFE-coated plates and sacrificial flash traps. Implement helium leak test protocol at 1E-6 mbar·l/s sensitivity.

Results: First pass yield rose from 85% to 98%. Leak failures reduced to <0.02%. Average cycle time: 72s per assembly; ROI in <18 months with automated feed & rotary indexing.

Keywords used: EV coolant tank welding, hot plate welding EV, IR preheat plastic welding, helium leak test battery tank.

Case Study B — Plastic Pallet Manufacturing (Hot Plate Fusion)

Challenge: Large HDPE logistic pallet with ribbed understructure to pass 3m drop tests while keeping cycle time cost-effective.

Solution: Design custom zoned hot plate tooling to support heavier ribbed areas and incorporate quick-release clamps. Optimize heating time & forge pressure per zone. Automated flash extraction and pallet conveyorized curing reduces downstream handling.

Results: Pallet yield improved to 96%; cycle time 4.5 min / pallet; passed 3m drop test consistently; scrap rate reduced 60%.

Keywords used: plastic pallet welding machine, hot plate pallet welding, 3m drop test pallet, HDPE pallet hot plate welding.

Case Study C — Bumper Bracket Ultrasonic Automation

Challenge: High-volume assembly of multiple small brackets and clips to a bumper carrier; manual insertion had high variability and labor cost.

Solution: Automated vibratory feeders for clips, integrated ultrasonic station with multi-sonotrode array, vision alignment and PLC-driven SKU selection via barcode.

Results: Cycle time per clip reduced to 0.9s, labor reduced by 72%, throughput improved by 40% and rework nearly eliminated.

Keywords used: bumper bracket ultrasonic welding, ultrasonic welding automation, clip welding machine.

Procurement Checklist — Selecting the Right Plastic Welding Machine Vendor

This procurement checklist helps OEMs and Tier-1 buyers compare vendors and machines on objective criteria.

Technical Fit

- Material compatibility & test samples

- Part size & required fixture adaptability

- Process monitoring & data output (energy, time, force logs)

Commercial & Service

- Lead times & spare parts availability

- Warranty & service level agreements (SLA)

- Training & on-site commissioning

- Local service presence & remote diagnostic support

Safety & Compliance

- CE / UL / local electrical compliance

- Machine guarding & interlocks

- Operator ergonomics & emergency stop strategy

Keyword Integration (Procurement)

plastic welding machine supplier, ultrasonic welding machine manufacturer, hot plate welding vendor, vibration welding equipment supplier, welding machine price & RFQ template.

SEO Keyword Coverage — Broad-Match & Long-tail Keyword Integration

Below is an extensive keyword cluster that was used across this article to maximize organic visibility for search terms related to plastic welding machines, automotive welding applications, and related buyer intents. Use these keywords for page meta, alt tags, subheadings, and internal anchor text to improve topical authority.

Primary & High-Value Keywords

- plastic welding machine

- welding plastic machine

- plastic weld machine

- hot plastic welding machine

- plastic pipe welding machine

- ultrasonic welding machine

- hot plate welding machine

- vibration welding machine

- infrared welding machine

- plastic pallet welding machine

Long-tail & Commercial Keywords (Examples)

- plastic welding machine for automotive

- ultrasonic welding machine automotive parts

- hot plate welding machine for fuel tank

- vibration welding intake manifold supplier

- infrared plastic welding EV coolant tank

- plastic pipe welding machine for auto fluid lines

- pallet 3m drop test welding machine

- plastic welding machine manufacturer China

- best plastic welding machine for PP

- plastic welding machine price list

Informational & Research Keywords

- how to weld plastic parts in automotive

- ultrasonic vs hot plate welding for plastic tanks

- plastic welding defect troubleshooting

- welding parameters for PP automotive parts

- design for ultrasonic welding energy director

- how to pass fuel tank helium leak test

- what is vibration welding

Local & Transactional Keywords

- plastic welding machine supplier USA

- buy ultrasonic welding machine Europe

- hot plate welding machine for sale

- plastic welding machine dealer near me

- industrial plastic welding machine price

Use these keywords in title tags, H1/H2/H3 headings, alt attributes for your images, and internal anchor links. For example, the anchor Ultrasonic Welding Machines — Product Page used above is a good internal anchor to link to product pages.

FAQ — Common Questions About Plastic Welding Machines in Automotive

Q: Which welding method is best for a HDPE fuel tank?

A: Hot plate welding is commonly used for HDPE fuel tanks due to thick wall sections and the need for deep melt and hermetic sealing. Helium leak testing is recommended for validation.

Q: Can ultrasonic welding handle glass-filled nylon parts?

A: Glass-filled nylons often require higher energy and more robust sonotrode materials. In many cases, vibration or hot plate welding provides more reliable joints for heavily filled materials.

Q: Is it possible to automate a pallet welding line?

A: Yes. Pallet production can be automated with conveyor indexing, robotic handling, automated flash removal and integrated leak/strength testing stations.

Q: How do I choose between ultrasonic and hot plate for a new part?

A: Consider part size, wall thickness, required weld strength, aesthetic limits (flash), and cycle time. Run sample tests with both methods if in doubt.

Q: Do you offer sample welding tests?

A: Yes — we do free feasibility tests in our weld lab. Contact us to arrange a sample test (WhatsApp is fastest): +86 15358007790.

Contact, Sample Tests & Next Steps

If you're evaluating plastic welding machines for automotive production (EV battery systems, fuel tanks, bumpers, dashboards, HVAC ducts, pallets), we can help with:

- Free sample welding tests (send drawings & material data)

- Custom fixture & sonotrode design

- Turnkey automation & MES integration

- On-site commissioning, training and service

Fastest contact method (WhatsApp):

📲 WhatsApp: +86 15358007790 — Request Sample Weld / RFQEmail: sales04@nicle.cn

Suggested internal links (replace with real URLs):

Suggested external authority links (for citation & trust signals):