Comprehensive Welding Solutions for Automotive Interior and Exterior Components

As the global automotive industry continues its transformation toward intelligent manufacturing, lightweight design, and sustainability, the demand for advanced plastic welding technologies has never been greater. From dashboards and door panels to bumpers and lighting systems, plastic components now dominate the construction of modern vehicles. Each of these parts requires a precise, durable, and efficient joining process—one that ensures both structural integrity and a flawless aesthetic appearance.

Automotive manufacturers and suppliers around the world are increasingly turning to advanced welding systems such as the ultrasonic welding machine, hot plate welding machine, vibration welding machine, heat staking machine, and laser welding machine to achieve high productivity and superior joint quality. Among the leading innovators in this field, Dizo Sonics has become synonymous with precision, reliability, and customization in plastic welding solutions for the automotive sector.

Why Plastic Welding is Essential for Automotive Manufacturing

In the past, traditional mechanical fasteners, adhesives, and screws were commonly used to assemble plastic automotive parts. However, as vehicle designs have become more complex and performance expectations more demanding, these traditional methods can no longer provide the strength, consistency, and clean appearance required in modern manufacturing. Plastic welding eliminates the need for foreign materials, creating strong molecular bonds that ensure airtight, watertight, and vibration-resistant joints.

The benefits of using advanced plastic welding machines in automotive production include:

- Enhanced structural integrity — The welded joint often becomes as strong as or stronger than the base material itself.

- Improved aesthetics — No need for screws or adhesives, allowing seamless, visually appealing designs.

- Increased efficiency — Automated welding processes significantly reduce cycle time and human error.

- Reduced weight — Perfect for lightweight automotive design requirements.

- Environmental benefits — Eliminates chemical adhesives and supports recyclable materials.

For example, the ultrasonic welding machine is now a standard tool for joining dashboard clips, air vents, and sensor housings, while the hot plate welding machine is preferred for larger parts such as bumpers, glove boxes, and tank assemblies.

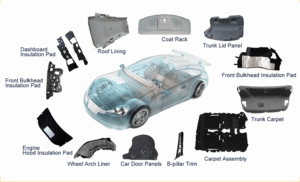

Interior and Exterior Automotive Parts That Rely on Plastic Welding

From interior comfort features to exterior aerodynamic designs, plastic components are everywhere in today’s vehicles. Here’s a closer look at the range of applications where Dizo Sonics’ plastic welding equipment plays a critical role:

Automotive Interior Components

- Instrument panels and dashboards: Ultrasonic and heat staking machines are commonly used to assemble multi-layer dashboard structures and integrate control modules.

- Door panels: Servo-controlled heat staking machines ensure clean and durable joints for plastic-to-metal and plastic-to-plastic fastening points.

- Air conditioning vents: Precision ultrasonic welding ensures air-tight seals without visible marks.

- Center consoles and cup holders: Compact ultrasonic systems provide strong and invisible welds even in tight assembly spaces.

- Electronic control housings: Laser welding machines deliver high-precision, dust-free joints for electrical safety.

Automotive Exterior Components

- Bumpers and grilles: Hot plate welding machines create robust, aesthetic, and dimensionally stable joints on large surface areas.

- Lamp housings and tail lights: Laser and vibration welding machines achieve optical-quality seams without deformation.

- Roof racks and spoilers: Ultrasonic welding ensures aerodynamic durability under mechanical stress.

- Washer and fuel tanks: Vibration welding provides perfect leak-proof seals that withstand pressure and temperature variations.

The Transition Toward Automation and Industry 4.0

As automotive factories integrate robotics, IoT, and digital monitoring systems, the demand for intelligent welding solutions continues to grow. Dizo Sonics is at the forefront of this evolution, offering automated welding workstations that combine mechanical precision with smart data tracking. Each system can be customized to communicate with production lines, ensuring consistent performance and traceability in real time.

Modern ultrasonic welding machines and vibration welding machines by Dizo Sonics come equipped with programmable logic controllers (PLCs), servo drives, and data interfaces compatible with Industry 4.0 platforms. These capabilities enable automotive manufacturers to achieve faster production cycles, lower scrap rates, and enhanced product traceability—all while maintaining top-tier quality standards.

For additional insight into Industry 4.0 trends in manufacturing, you can refer to McKinsey’s Industry 4.0 Report.

Challenges in Automotive Plastic Welding and How Dizo Sonics Addresses Them

Despite the benefits of plastic welding, automotive manufacturers often face several challenges during production:

- Material variation: Different thermoplastics like PP, ABS, PC, and nylon have unique melting characteristics that require fine control of heat and pressure.

- Complex geometry: Many modern parts have multi-dimensional surfaces that make traditional welding difficult.

- Cosmetic quality: Visible parts like interior trims and lamp housings demand invisible seams and clean surfaces.

- Cycle time optimization: In high-volume production, every second counts—requiring machines that can deliver repeatable results rapidly.

Dizo Sonics provides a solution for each of these challenges through its modular system design, multi-process integration, and R&D-driven customization. Each Dizo Sonics welding machine is engineered for precision control, user-friendly interfaces, and long-term reliability under continuous industrial operation.

Global Reach and Market Influence

With installations across Asia, Europe, and North America, Dizo Sonics has supported leading automotive manufacturers and Tier-1 suppliers in achieving consistent, high-quality welds for plastic components. The company’s products, including ultrasonic welding machines, hot plate welding machines, vibration welding machines, and heat staking systems, are designed to meet diverse production demands across global markets.

Each system is built with international safety standards and CE certification, providing confidence for customers worldwide. Dizo’s commitment to innovation and sustainability ensures that its welding solutions remain a cornerstone of the modern automotive manufacturing ecosystem.

Comparison of Key Welding Technologies for Automotive Plastic Components

When it comes to joining automotive plastic parts, choosing the right welding method directly impacts the product’s appearance, strength, and cost-efficiency. Among the most widely used processes in the automotive industry are ultrasonic welding, hot plate welding, vibration welding, and heat staking. Each technique offers unique advantages depending on material type, part geometry, and production scale.

1. Ultrasonic Welding Machine

The ultrasonic welding machine is the most popular equipment for small and medium-sized plastic automotive components. It uses high-frequency mechanical vibrations—typically in the range of 20–40 kHz—to generate localized heat and fuse thermoplastic materials at the joint interface.

- Advantages: Fast cycle times, no need for additional materials, compact footprint, ideal for automation.

- Applications: Air vents, sensor housings, electronic enclosures, and decorative trims.

- Key Feature: Servo-controlled ultrasonic systems ensure consistent energy delivery, precision amplitude control, and repeatable welding results.

For a detailed breakdown of ultrasonic welding principles, visit the external resource ScienceDirect: Ultrasonic Welding Overview.

2. Hot Plate Welding Machine

The hot plate welding machine is designed for large, complex, or three-dimensional parts that require strong, uniform joints. It works by pressing the surfaces of the plastic components against a precisely controlled heated plate until the material reaches a molten state. The plate is then removed, and the parts are pressed together to form a permanent bond.

- Advantages: Excellent hermetic sealing, strong structural welds, suitable for large or uneven surfaces.

- Applications: Automotive bumpers, glove boxes, fuel tanks, and intake manifolds.

- Key Feature: Dizo Sonics’ machines utilize dual-zone temperature control and servo motion systems for high precision.

Compared with ultrasonic systems, hot plate welding can join dissimilar plastics and thicker components, making it a preferred method for exterior and under-the-hood applications.

3. Vibration Welding Machine

The vibration welding machine is a versatile solution for medium to large parts where structural integrity and sealing are critical. It joins plastics by creating frictional heat through high-frequency linear or orbital vibration under pressure.

- Advantages: Capable of welding large surface areas, high joint strength, and compatibility with complex geometries.

- Applications: Air intake manifolds, lighting housings, washer reservoirs, and filter assemblies.

- Key Feature: Servo-driven vibration systems allow precise control of amplitude and frequency for consistent results.

This process is widely used in fuel and air management systems because it ensures completely leak-proof joints, even in pressure-sensitive assemblies. Dizo Sonics’ advanced vibration welders are specifically engineered to minimize particle generation, making them suitable for clean-room environments as well.

4. Heat Staking Machine

The heat staking machine is ideal for joining plastic components with metal inserts or dissimilar materials. The process involves locally heating plastic bosses or studs, reshaping them through controlled pressure, and forming a mechanical bond once cooled.

- Advantages: Works with multi-material assemblies, gentle on electronics, strong mechanical fixation.

- Applications: Door panels, electronic modules, airbag housings, and center consoles.

- Key Feature: Servo-controlled heat staking allows for programmable temperature and force profiles for precision results.

Compared to adhesive or screw-based assembly, heat staking offers cleaner aesthetics, reduced vibration noise, and lower production costs. It is especially common in automotive interior trim assembly lines.

5. Laser Welding Machine

Laser welding is a non-contact joining process that uses a focused laser beam to heat and melt the interface between plastic components. It is best suited for transparent or semi-transparent plastics, offering clean, particle-free seams with exceptional accuracy.

- Advantages: Precise and aesthetic joints, minimal thermal stress, suitable for sensitive electronics.

- Applications: Lighting covers, sensor housings, and instrument clusters.

While laser welding systems are typically more expensive, they are becoming increasingly popular in luxury vehicle production due to their unmatched visual quality and repeatability. Learn more from Automotive Manufacturing Solutions.

Choosing the Right Welding Machine for Automotive Applications

Selecting the optimal welding process requires careful consideration of factors such as part material, geometry, production volume, and quality requirements. Dizo Sonics engineers work closely with OEMs and Tier-1 suppliers to design custom systems that deliver perfect welds every time.

| Welding Type | Best For | Material Compatibility | Cycle Time | Weld Strength |

|---|---|---|---|---|

| Ultrasonic Welding | Small parts, tight tolerances | ABS, PP, PC, PS | Very Fast | Moderate to High |

| Hot Plate Welding | Large, complex parts | PP, HDPE, PA, POM | Medium | High |

| Vibration Welding | Medium to large components | PP, PA, PET, PBT | Medium | Very High |

| Heat Staking | Plastic + metal assemblies | All thermoplastics | Fast | High mechanical fixation |

| Laser Welding | Visible, transparent parts | PMMA, PC, PET | Fast | High, aesthetic |

For an expert consultation or demo request, visit Dizo Sonics Contact Page to connect with our engineering team.

Cost Efficiency and Return on Investment (ROI)

For automotive manufacturers, production efficiency and return on investment are critical considerations when selecting a plastic welding system. Each process—whether it’s ultrasonic, vibration, or hot plate welding—has its own economic profile depending on the complexity and scale of production.

Initial Investment vs. Production Volume

Ultrasonic welding machines are known for their low entry cost and extremely fast cycle times, making them ideal for mass production of small to medium plastic components. The ultrasonic welding machine offers the highest throughput at the lowest cost per weld, which is why it remains the most common choice for dashboard clips, lamp housings, and electronic connectors.

In contrast, the hot plate welding machine involves a slightly higher initial investment but delivers stronger and more airtight joints, especially for large automotive parts like fuel tanks, bumpers, and glove boxes. Over time, the durability of these welds results in reduced defect rates and lower overall maintenance costs.

The vibration welding machine is positioned between these two technologies. Its flexible setup makes it suitable for medium-to-high production runs, particularly for components requiring structural integrity, such as instrument panels and air intake manifolds. When compared to adhesive bonding, vibration welding can reduce cycle time by 40–60% and eliminate consumables altogether.

Energy Consumption and Operating Costs

Modern welding systems are designed to align with sustainability goals and energy efficiency standards. For example, Dizo Sonics integrates servo-controlled systems that minimize idle power usage while ensuring precise heat application. Compared to traditional resistance welding or adhesive curing ovens, ultrasonic and heat staking systems consume up to 70% less energy.

Furthermore, the absence of consumables—such as glue, solvents, or fasteners—not only reduces costs but also contributes to a cleaner production environment. This supports the global automotive industry's push toward UN Sustainable Development Goals (SDG 12 – Responsible Consumption and Production).

Automation and Industry 4.0 Integration

With the rise of smart factories and digital manufacturing, automation plays a central role in achieving consistent weld quality and traceability. Dizo Sonics provides fully automated workstations for its ultrasonic welding machines, hot plate welders, and vibration welding machines. These systems can be seamlessly integrated with robotic arms, PLC controllers, and MES systems to ensure real-time monitoring and data collection.

For instance, servo-controlled heat staking machines allow programmable temperature profiles and force feedback monitoring, ensuring every staking point meets exact design specifications. Similarly, laser welding machines can be equipped with real-time vision systems to inspect weld seams automatically, reducing human error and rework costs.

To learn more about automated welding trends, visit Automation World, which highlights how automation reshapes modern automotive assembly lines.

Sustainability and Environmental Benefits

Beyond cost and efficiency, sustainability has become a major driver in selecting the right welding technology. All plastic welding machines from Dizo Sonics are designed to minimize material waste and energy consumption. The elimination of adhesives and solvents reduces VOC emissions, while optimized heat transfer lowers electricity demand.

In the context of electric vehicle (EV) production, clean and precise welding methods such as ultrasonic and laser welding are increasingly favored because they avoid contamination and ensure consistent joint integrity, especially in battery housing and sensor module assembly.

Moreover, technologies like vibration welding and hot plate welding support the recycling of thermoplastics since they don’t introduce foreign materials into the weld. This simplifies end-of-life disassembly and contributes to a circular economy.

Future of Automotive Plastic Welding

As vehicle design trends move toward lightweight, integrated, and modular structures, the demand for advanced welding technologies will continue to rise. Automotive manufacturers are increasingly adopting hybrid joining systems that combine multiple techniques—such as ultrasonic pre-welding followed by laser sealing—to achieve both speed and aesthetic quality.

The integration of AI-based quality control and real-time process analytics will soon make welding smarter and more adaptive. Dizo Sonics is already developing intelligent control algorithms that analyze vibration frequency, amplitude, and energy signatures to predict weld outcomes before failure occurs.

For large-scale production, modular welding cells that can switch between ultrasonic and vibration modes are also emerging. These hybrid systems can significantly improve equipment utilization rates and shorten changeover times.

Partnering with Dizo Sonics

With over 15 years of expertise in plastic welding solutions, Dizo Sonics stands as a global leader in ultrasonic, hot plate, vibration, and heat staking technology. Our R&D team collaborates with leading automotive suppliers to develop custom solutions that address evolving manufacturing needs. Each Dizo system is designed for high precision, minimal maintenance, and long service life.

Dizo’s product range includes:

- Ultrasonic Welding Machines

- Hot Plate Welding Machines

- Vibration Welding Machines

- Heat Staking Machines

By combining automation, precision control, and a deep understanding of thermoplastic materials, Dizo Sonics delivers tailored solutions that meet the strictest automotive standards worldwide.

Conclusion: Driving the Future of Automotive Plastic Welding

Automotive interior and exterior components rely on strong, clean, and precise joints to meet modern design and safety requirements. The right welding machine—whether ultrasonic, hot plate, vibration, or laser—can make the difference between an efficient production line and costly rework. As the industry evolves toward smarter and greener manufacturing, Dizo Sonics continues to lead innovation with intelligent control systems and globally trusted reliability.

If your company is seeking a trusted partner for advanced plastic welding systems, contact Dizo Sonics today for a free consultation or to request a custom quotation. Together, we’ll shape the future of automotive manufacturing.