🔹 Introduction

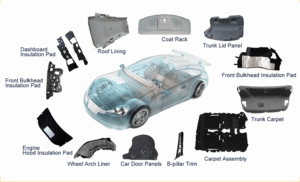

In modern logistics and warehouse industries, plastic pallets have become a preferred choice due to their durability, lightweight, and recyclability.

However, manufacturing large and heavy-duty plastic pallets requires strong and reliable welding technology — not every method can achieve that.

In this article, we’ll explain how to weld plastic pallets, compare different welding methods, and show why hot plate welding machines are the most efficient solution for large pallet structures.

🔹 Why Welding Matters in Plastic Pallet Manufacturing

A typical plastic pallet is made of HDPE (High-Density Polyethylene) or PP (Polypropylene).

Because of its large surface area and thick wall sections, it’s often impossible to produce in one single mold — manufacturers usually weld the upper and lower parts together.

The quality of the weld directly affects:

Load-bearing capacity

Drop impact resistance

Dimensional stability

Service life during transportation and reuse

Therefore, choosing the right plastic pallet welding process is critical.

🔹 Common Welding Methods for Plastic Pallets

| Welding Method | Suitable Materials | Advantages | Limitations |

|---|---|---|---|

| Ultrasonic Welding | Thin to medium-thickness thermoplastics | Fast, clean, energy-efficient | Not ideal for large pallets (limited welding area) |

| Hot Plate Welding | Large HDPE / PP components | Uniform heating, strong joints, perfect for large pallets | Slightly longer cycle time |

| Spin Welding / Vibration Welding | Circular or flat parts | Strong welds | Limited part geometry |

👉 For plastic pallets, Hot Plate Welding is the most widely used and reliable process.

🔹 How Hot Plate Welding Works

Hot plate welding uses a heated metal plate to melt the contact surfaces of two plastic parts.

After melting, the hot plate is removed, and the two parts are pressed together under controlled pressure until the material solidifies — creating a molecular-level bond.

Welding Steps:

Positioning – Pallet halves are aligned and clamped.

Heating – The hot plate moves between parts, heating both surfaces.

Melting – Surfaces soften to the proper depth.

Joining – The plate retracts, and the halves are pressed together.

Cooling – Pressure is maintained until the joint solidifies.

This process ensures uniform, strong, and airtight welds, ideal for heavy-duty plastic pallets used in logistics and automotive industries.

Plastic welding machine demo video

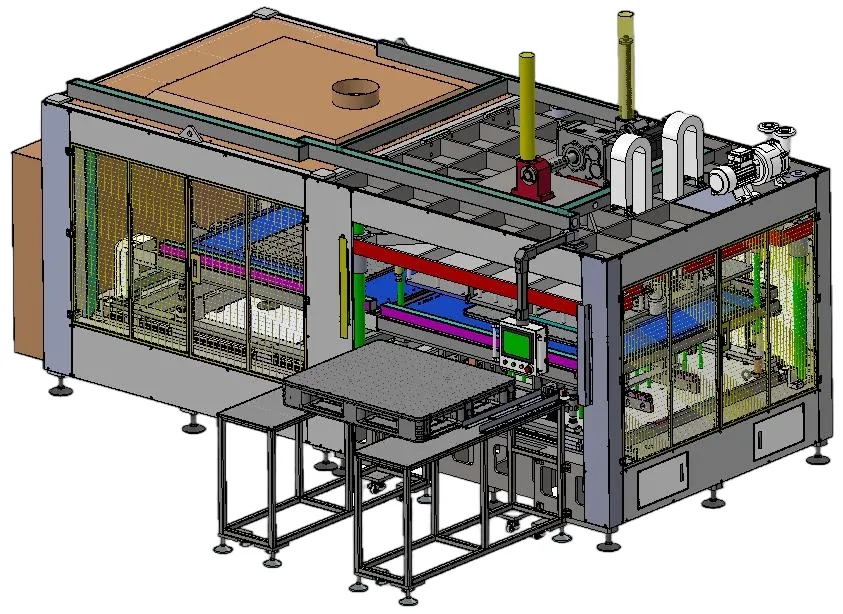

Equipment: Hot Plate Plastic Pallet Welding Machine

At Dizo Ultrasonics, we provide automatic hot plate welding machines specially designed for plastic pallet production.

Key Features:

Suitable for large HDPE and PP pallets

Servo or hydraulic drive for stable and precise motion

Automatic heating, joining, and cooling cycles

Touch-screen control (HMI + PLC) for easy operation

Custom tooling design for different pallet sizes

Optional auto loading & unloading system for high productivity

💡 Dizo’s hot plate pallet welding system helps manufacturers reduce injection molding tonnage and initial investment — while maintaining high structural integrity.

🔗 Related product:

Plastic Pallet Hot Plate Welding Machine – Dizo Ultrasonics

🔹 Drop Test Example: Proving the Strength

To verify the joint quality, Dizo Ultrasonics conducted a 3-meter drop test on welded plastic pallets.

The result: no cracks, no deformation, and excellent weld strength — demonstrating the reliability of hot plate welding technology.

“Plastic Pallet 3-Meter Drop Test After Welding | Dizo Ultrasonics”

🔹 Conclusion

If you’re producing large plastic pallets for automotive, logistics, or warehouse applications, investing in a hot plate welding solution is the key to achieving:

Lower production costs

Higher structural strength

Reduced mold tonnage

Longer pallet lifespan

Dizo Ultrasonics offers complete plastic pallet welding solutions, including machine customization, fixture design, and process optimization.

📩 Contact us today to discuss your pallet welding needs:

👉 Request a Quote