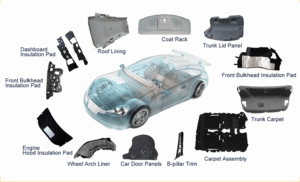

In modern automotive manufacturing, plastic welding technology plays a crucial role in achieving lightweight designs, tight sealing, and high structural strength. Dizo Ultrasonic Technology (Dizo Sonics) is a global supplier of ultrasonic and hot plate welding systems engineered specifically for automotive plastic components — from bumpers and lamp housings to dashboards and fluid tanks.

Why Automotive Manufacturers Trust Dizo