🏭 Understanding Plastic Pallet Types and Their Welding Process Differences

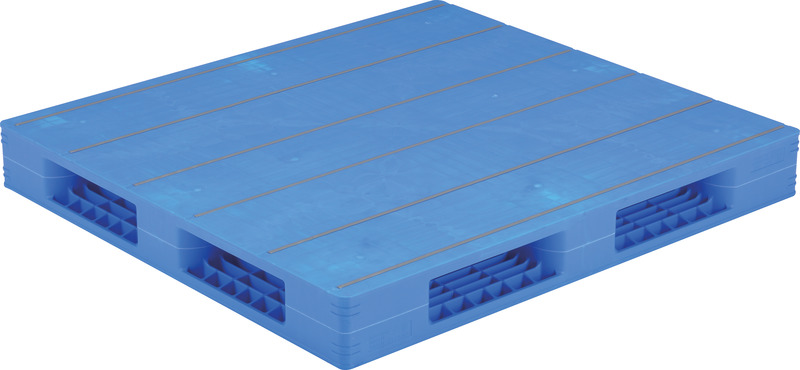

Plastic pallets are the backbone of modern logistics, replacing traditional wooden pallets with stronger, cleaner, and more sustainable options.

As automation spreads through warehouses and factories, plastic pallet welding machines—especially hot plate welding systems—have become essential in producing durable, cost-efficient pallets for different applications.

This article explains the classification of plastic pallets, the design logic behind each type, and the different welding methods required to achieve consistent quality.

How Plastic Pallets Are Classified

Plastic pallets are classified by application, structure, và material composition.

Each factor directly affects the welding process, temperature settings, và machine design used during manufacturing.

1. Classification by Application

| Type | Common Uses | Key Features |

|---|---|---|

| Hygiene Plastic Pallets | Food, Beverage, Pharmaceutical | Smooth, easy to clean, no cavities |

| Heavy-Duty Plastic Pallets | Industrial, Warehouse, Export | High load capacity, often reinforced with steel pipes |

| Double Face Plastic Pallets | Automated warehouses, closed-loop logistics | Two usable sides, excellent stability |

| Lightweight Plastic Pallets | One-way transport, export packaging | Economical and recyclable |

| Warehouse / Returnable Pallets | Automated storage, conveyor systems | Precise dimensions, reusable |

Double face plastic pallets are widely used in automated warehouses và racking systems, where both sides of the pallet need to support loads. Their design ensures uniform strength and better load distribution, but it also makes welding precision more critical.

2. Classification by Structural Design

| Structure Type | Design Example | Welding Implication |

|---|---|---|

| Single Deck Pallet | One side usable | Simplified welding, faster cycle |

| Double Deck (Double Face) Pallet | Both sides usable | Requires dual-face alignment, longer welding time |

| Three-Runner Pallet | Three base runners under the deck | Requires precise runner alignment |

| Nine-Foot Pallet | 9 support feet for stacking | Low welding pressure, short heating cycle |

| Perimeter Base Pallet | Full outer frame design | Requires balanced heat distribution |

Double face pallets are essentially double-decked structures, meaning both the top and bottom decks are welded together along a broad joining surface.

This design provides exceptional strength but requires longer heating and cooling cycles to prevent internal stress or deformation.

3. Classification by Material Composition

| Vật liệu | Characteristics | Welding Consideration |

|---|---|---|

| HDPE (Polyethylene mật độ cao) | Flexible, impact-resistant | Moderate temperature, slower cooling |

| PP (Polypropylene) | Rigid, chemical-resistant | Higher temperature, shorter heating time |

| Recycled PP/PE Blends | Cost-effective | Variable melting points, needs monitoring |

| Glass-Fiber Reinforced PP | Enhanced rigidity | Requires stable, evenly distributed heat |

Welding Process for Different Plastic Pallet Types

Plastic pallets are often molded in halves and then joined using Hàn bằng tấm gia nhiệt.

This allows manufacturers to use smaller injection molding machines and reduce tonnage and equipment investment, while still ensuring a solid final product.

🔗 Related: How Plastic Pallet Welding Reduces Initial Investment

1. Welding Hygiene Plastic Pallets

Material: HDPE

Goal: Maintain contamination-free surfaces

Welding Settings:

Temperature: 220–280°C

Moderate pressure to avoid surface marks

Clean plate surface and automatic residue removal

2. Welding Heavy-Duty Plastic Pallets

Material: PP or reinforced PP

Structure: Double deck, reinforced with steel pipes

Welding Focus:

Higher temperature (250–280°C)

Precise pressure balancing

Extended welding and cooling time

These pallets must maintain dimensional accuracy for warehouse automation systems and racking use.

3. Welding Double Face Plastic Pallets

Structure: Two identical decks welded together

Thách thức: Full-surface bonding and temperature balance

Welding Focus:

Use large-area heating plates with uniform heat distribution

Control heating time carefully to avoid warping

Apply servo-controlled pressure for consistent parallel bonding

Ensure slow cooling to maintain flatness

💡 Because double-face pallets have no open space for stress release, their cooling process is critical.

Dizo integrates intelligent cooling zones in its machines to prevent surface warpage.

4. Welding Three-Runner Plastic Pallets

Material: PP/HDPE mix

Welding Focus:

Align runners precisely before heating

Use multi-zone temperature control

Prevent shrinkage at runner ends during cooling

5. Plastic pallet welding machine demo test video

6. Welding Lightweight or Nine-Foot Pallets

Material: Recycled HDPE

Focus:

Lower temperature and shorter cycle

Prevent over-compression

Air-cooling for fast solidification

These pallets are commonly used in export packaging, where cost efficiency is key.

Key Welding Factors for Plastic Pallets

| Factor | Importance |

|---|---|

| Temperature Control | Prevents surface burn and ensures deep fusion |

| Pressure Consistency | Guarantees structural symmetry |

| Cooling Time | Reduces internal stress and deformation |

| Mold Alignment | Critical for double face and three-runner types |

| Surface Cleanliness | Essential for hygiene pallets |

Dizo’s welding systems combine digital PID control, hydraulic equalization, và real-time monitoring, ensuring repeatable, high-quality welds across all pallet types.

Selecting the Right Plastic Pallet Welding Machine

When investing in a welding machine, consider:

Pallet size and weight

Type (hygiene, double face, three-runner)

Production speed

Material composition

Automation requirements

Double face plastic pallet final product after welding

Conclusion

Plastic pallets—ranging from hygienic to heavy-duty, three-runner, và double-face designs—each require tailored welding parameters and equipment configurations.

By mastering these differences, manufacturers can reduce production costs, improve structural performance, và increase long-term ROI.

With over 15 years of industry experience, Dizo Sonics provides reliable plastic pallet welding solutions trusted by pallet manufacturers worldwide.