Complete Guide to Ultrasonic Welding Machines | Dizo Sonics

1. Introduction to Ultrasonic Welding

In the era of intelligent manufacturing, ultrasonic welding machines are transforming how companies produce plastic and composite components. Dizo Sonics, a leading ultrasonic equipment manufacturer, delivers custom welding systems designed for precision, reliability, and sustainability — all built to meet your production goals. Learn more at Dizo Sonics Official Website.

2. Why Leading Manufacturers Choose Dizo

Expertise in Ultrasonic Innovation

With over 15 years of engineering excellence, Dizo has become a trusted provider of ultrasonic welding and cutting solutions. Our R&D team collaborates with top universities to ensure every machine integrates the latest in smart manufacturing technology.

Visit About Us: Sobre a Dizo Sonics

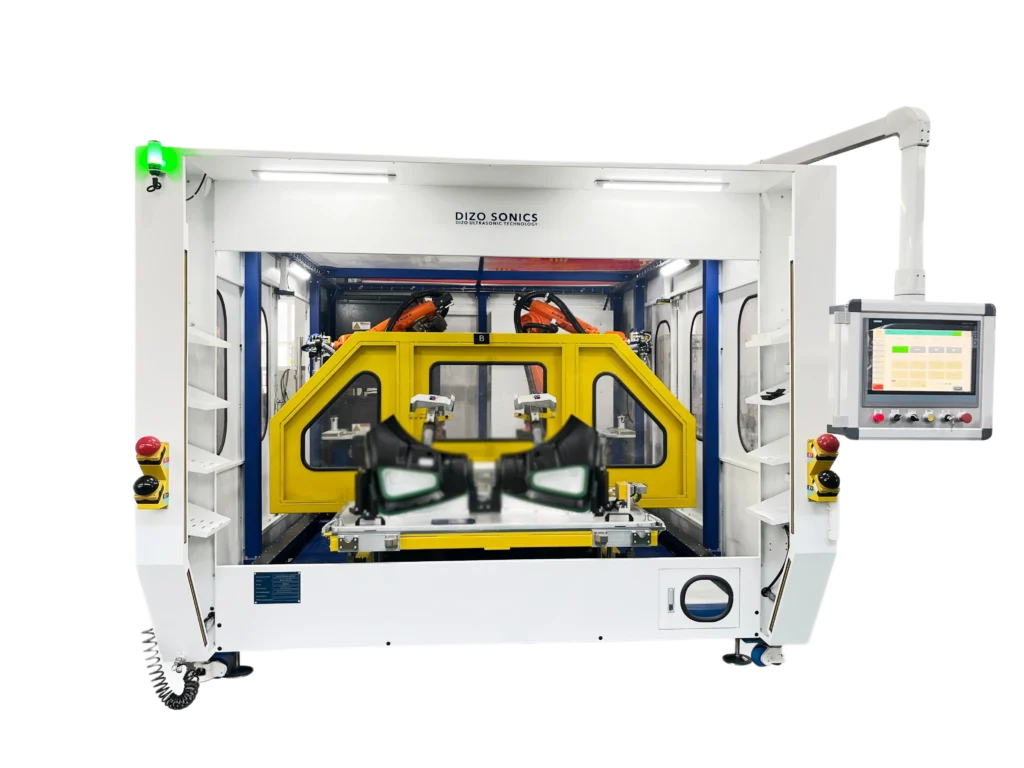

3. Fully Customizable Welding Systems

Dizo offers tailor-made ultrasonic welding equipment to match your specific materials, shapes, and production capacity. We provide free testing, operator training, lifetime support, and fast global delivery.

Explore product range: Dizo Sonics Products

4. Comprehensive Product Line

- Multi-head ultrasonic welding machines for large automotive parts

- Robotic ultrasonic welding workstations for smart production lines

- Ultrasonic welding & punching machines for bumpers and sensors

- Hot plate welding machines for heavy-duty plastic pallets

Hot Plate Welding Machine: Plastic Pallet Hot Plate Welding

5. Industries We Serve

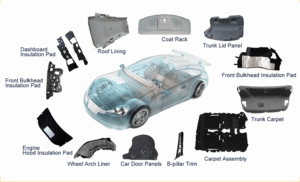

- Automotive: bumpers, lamp housings, dashboards

- Consumer Electronics: sealed housings, connectors

- Industrial & Logistics: plastic pallets, storage bins

- Medical & Packaging: clean welding without adhesives

Applications & Cases: View Case Studies

6. Quality & Support That Lasts

- Lifetime technical support & one-year warranty

- Global after-sales response within 8 hours

- Transparent manufacturing process

- Optional on-site setup and operator training

Contact: Dizo Sonics Contact

7. Industry Applications

7.1 Automotive Components

Ultrasonic welding is ideal for dashboards, door panels, trims, bumpers, and lighting housings. Learn more: Automotive Solutions

7.2 Consumer Electronics

Sealed housings, wire harness encapsulation, and safe PCB enclosures. Reference: Electronics Weekly

7.3 Industrial Plastics and Pallets

Reduces injection molding tonnage and enhances structural integrity. Reference: Plastic Pallet Welding

7.4 Medical and Packaging

Ensures hygiene and sterility without adhesives. Reference: Medical Devices Study

8. Technical Advantages

- Precision and Repeatability

- Energy Efficiency

- Smart Manufacturing Integration

- Reduced Initial Investment

9. Customer Success Stories

Examples include automotive, electronics, and industrial pallet manufacturers achieving faster cycles, reduced defect rates, and cost savings.

10. Market Insights

Vietnam ultrasonic welding market grows ~15% per year. Global demand driven by quality, energy efficiency, and automation. Reference: Plastics News

11. Comparative Analysis

| Method | Main Features | Advantages | Limitations |

|---|---|---|---|

| Soldagem ultrassônica | High-frequency vibrations create localized heat | Fast, clean, energy-efficient, precise | Limited thickness range, certain material types |

| Soldagem por placa quente | Heated plate melts plastics | Good for large/thick parts | Slower, higher energy use |

| Soldagem por vibração | Mechanical friction via oscillation | Large-area welds possible | Noise, vibration, requires sturdy fixtures |

| High-Frequency Welding | Radio-frequency heating for PVC/PU | High-quality aesthetic welds | High initial investment, electrical safety concerns |

12. Support and Services

- 12-month standard warranty

- 24/7 technical support

- Global fast delivery

- On-site installation and operator training

- Lifetime consultation

Learn more: Dizo Sonics Services

13. Future Trends

- Robotics Integration

- Smart Manufacturing with IoT

- Energy-efficient generators

- Advanced material welding

- Global standards compliance

Reference: ScienceDirect

14. Investment Benefits

- Reduced production costs

- Lower capital investment

- Increased production efficiency

- Improved product quality

- Long-term support

Explore: Plastic Pallet Welding Solutions

15. Conclusion

- Advanced precision and clean welds

- Customizable solutions

- Global support network

- Energy efficiency and cost savings

- Smart manufacturing integration

Contact: Dizo Sonics

16. Call to Action – Request a Free Consultation

- Website: https://dzsonics.com/en/

- Products: Máquinas de solda ultrassônica

- Email:sales04@nicle.cn

View real-world examples: Case Studies