L'évolution des applications des polymères dans les intérieurs automobiles modernes

1.1. How Advanced Polymers Revolutionized Automotive Interior Design (2025 Data)

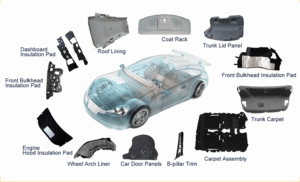

Automotive interior plastic parts have undergone a remarkable transformation over the past decade, with engineered polymers now dominating material selection across vehicle segments. This evolution represents a fundamental shift in how manufacturers approach interior design, balancing performance requirements with increasingly stringent sustainability mandates while creating lighter, more durable car interior components.

1.2. Current State Analysis: Automotive Interior Plastics in Premium to Mass-Market Vehicles

According to IHS Markit’s “2024-2025 Automotive Materials Outlook,” [Source: IHS Markit, 2024] plastic parts now constitute approximately 60% of the weight share in modern vehicle interiors, a significant increase from 42% just a decade ago. This transition spans all market segments, though with notable variations in implementation. Premium manufacturers like Mercedes-Benz and BMW have pioneered high-performance polymer applications, particularly in structural components, while mass-market producers have focused on cost-effective solutions that maintain adequate performance metrics.

Material distribution analysis reveals polypropylene (PP) dominates at 32% of interior plastics by weight, followed by polyurethane (PU) at 17%, and acrylonitrile butadiene styrene (ABS) at 14%. Recent SAE technical papers (SAE 2024-01-0456) [Source: Society of Automotive Engineers, 2024] document accelerating adoption of engineering-grade polymers, particularly in structural applications previously reserved for metals. This trend is particularly pronounced in electric vehicle interiors, where lightweight polymer solutions have accelerated the integration of advanced car interior plastic parts. Tesla’s Model Y, for example, utilizes over 35% recycled polypropylene in non-visible interior components, demonstrating real-world implementation of sustainable practices in modern automotive design.