Guía definitiva de la máquina de soldadura de placa caliente para la fabricación de plástico (actualización 2025)

Plastic manufacturing is entering a new era in 2025. With the rise of logistics automation, EV automotive components, reusable packaging, and industrial containers, plastic welding technology has become more demanding, more precise, and more intelligent. Among various plastic joining technologies, the soldadora de placas calientes remains one of the most reliable methods for welding large and complex thermoplastic parts such as plastic pallets, automotive interior structures, storage boxes, IBC tanks, PP/PE containers, and more.

This comprehensive guide will help you fully understand the soldadora de placas calientes, from working principles to real industrial applications and recent 2025 technical updates. Whether you're working in logistics packaging, automotive manufacturing, recycling plastics, or industrial equipment production, this guide helps you choose the right equipment, improve production efficiency, and achieve high-strength permanent welding results.

📌 What is a Hot Plate Welding Machine?

A soldadora de placas calientes (also called hot platen welder or heat staking welding machine) is a thermoplastic joining system that uses a precisely controlled heated plate to melt plastic surfaces, then presses the parts together to fuse permanently.

Compared with ultrasonic, vibration, or laser welding, the hot plate welding method is ideal for thicker, large-size, or uneven surface plastic components. It delivers strong bonding and airtight sealing without internal stress damage.

🔥 Why Hot Plate Welding Machine is Popular in 2025

- Growing plastic pallet and reusable container production

- Automotive lightweight EV structure expansion

- Demand for weld quality on thick PP/PE/HDPE materials

- Recycling & circular economy driving multi-layer plastic welding

- Smart factory automation trend

⚙️ How Hot Plate Welding Works

- Parts are clamped in fixtures

- Hot plate moves between parts

- Heating to melting temperature (usually 180–300°C)

- Hot plate retracts

- Parts press together under controlled pressure

- Cooling cycle forms permanent bond

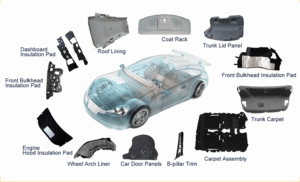

🏭 Industrial Applications of Hot Plate Welding Machine

- Plastic pallets (HDPE / PP)

- Automotive bumpers & dashboards

- Air ducts / EV battery plastic covers

- Large water tanks / IBC tanks

- Crates, containers, logistics boxes

- Recycling & regrind plastic structures

📊 Comparison: Hot Plate vs Ultrasonic vs Vibration vs Laser Welding

| Technology | Best For | Strength | Size Capability |

|---|---|---|---|

| Máquina de soldadura de placas calientes | Large PP/PE parts, pallets, tanks | ★★★★★ | Very Large |

| Máquina de soldadura por ultrasonidos | Small precision parts | ★★★★☆ | Small/Medium |

| Máquina de soldadura por vibración | Rectangular HDPE tanks | ★★★★★ | Large |

| Laser Welding | Clear/Black layered plastics | ★★★★★ | Small/Medium |

Learn more about vibration and ultrasonic welding at authoritative sources:

💡 2025 Technology Innovations

- Servo-driven platen movement

- AI temperature control

- Digital pressure monitoring

- Automatic part recognition & recipe load

- Predictive maintenance

🏆 Why Manufacturers Choose Dizo Sonics Hot Plate Welding Machine

Dizo Sonics is a professional industrial welding solutions provider, specializing in hot plate welding technology for plastic pallets, IBC tanks, automotive components, and industrial storage products.

Visit product page: Máquina de soldadura de placas calientes de paletas de plástico

💬 Customer Success Case: Plastic Pallet Factory

A large logistics pallet manufacturer reported:

- Production efficiency +62%

- Weld strength +55%

- Scrap rate reduced to <0.8%

📐 Key Specifications of Hot Plate Welding Machine

| Parameter | Value |

|---|---|

| Heating Plate Material | Aluminum Alloy / Ceramic Coated |

| Temperature Range | 100°C–350°C |

| Clamping Force | Up to 30 Tons |

| Control | PLC + Servo |

| Materiales adecuados | PP, PE, HDPE, ABS, PA |

📸 More Machine Views

📞 Contact Dizo Sonics for Custom Solutions

Looking to weld large industrial plastic parts efficiently and economically? Dizo Sonics offers automated and servo-controlled hot plate welding machines customized for your production needs.

Get Welding Consultation Now❓ FAQ

Which materials can be welded by hot plate welding?

PP, PE, HDPE, ABS, PA, TPO and composite plastics.

What industries use hot plate welding machines?

Logistics pallets, automotive components, industrial tanks, packaging boxes, battery covers.

Can hot plate welding be automated?

Yes, Dizo Sonics provides full automation + robotic loading systems.

🚀 Final Thoughts

The hot plate welding machine continues to be a cornerstone in heavy-duty thermoplastic welding, especially in logistics and automotive manufacturing. In 2025, AI-driven precision, servo technology, and digital quality control make the equipment smarter and more efficient than ever. If your products require structural strength, large size, and permanent bonding — hot plate welding is your best solution.

Request Quote From Dizo Sonics