Ultrasonic Welding Machine Market in Vietnam: Growth, Applications, and Opportunities

In recent years, Vietnam has become one of the fastest-growing manufacturing centers in Southeast Asia. With rapid industrial expansion in sectors like automotive, electronics, and packaging, the demand for advanced manufacturing technology such as the ultrasonic welding machine has increased dramatically. This article explores the current situation, opportunities, and challenges of the ultrasonic welding machine market in Vietnam, focusing on local manufacturing trends, industry applications, and how companies like Dizo Ultrasonic Technology provide reliable welding solutions for the region.

1. Overview of the Ultrasonic Welding Machine Industry in Vietnam

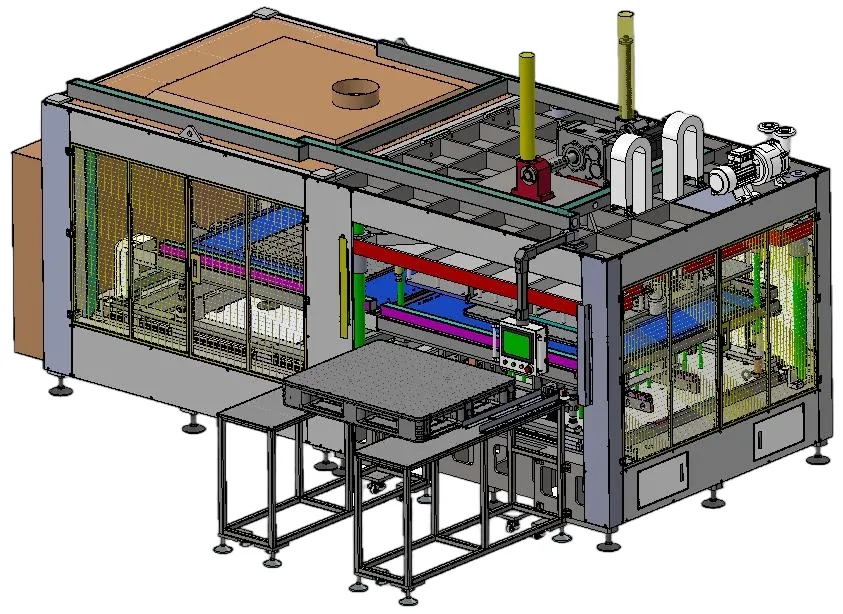

The ultrasonic welding machine is widely recognized as a key technology for joining plastic and metal components without using adhesives or fasteners. In Vietnam, this technology has become increasingly popular due to its efficiency, environmental benefits, and low maintenance requirements.

According to Statista and Vietnam News, the country’s manufacturing output has grown by more than 9% annually, creating strong demand for reliable and automated welding equipment. The ultrasonic welding machine is used in various sectors, including:

- Automotive parts and components (lamp housings, dashboards, sensors)

- Consumer electronics (mobile casings, connectors, batteries)

- Plastic pallets and industrial packaging

- Medical and hygiene products

2. Why Ultrasonic Welding Machines Are Ideal for Vietnam’s Manufacturing Sector

Vietnam’s competitive advantage lies in its labor cost and increasing investment in smart factories. However, traditional assembly methods such as screw fastening or gluing can limit production speed and product quality. By adopting a ultrasonic welding machine, manufacturers can achieve:

- Higher precision: Ultrasonic welding creates consistent joints with minimal deformation.

- Energy efficiency: The process consumes far less power than heat sealing or injection molding.

- Clean process: No adhesives or solvents — ideal for hygiene-critical industries.

- Automation-ready: Easy integration with robotic systems and smart manufacturing lines.

As Vietnam moves toward Industry 4.0, many factories in Bac Ninh, Dong Nai, and Ho Chi Minh City are already upgrading their production lines with ultrasonic welding machines to improve competitiveness.

3. Key Applications of Ultrasonic Welding Machines in Vietnam

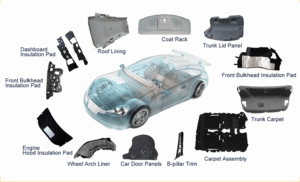

Automotive Manufacturing

With major players such as VinFast and Toyota Vietnam expanding local production, ultrasonic welding technology has become indispensable. It ensures lightweight yet durable parts — crucial for vehicle efficiency and safety. The ultrasonic welding machine is widely used for bumpers, lamps, interior panels, and sensor housings.

Plastic Pallet and Industrial Packaging

Vietnam’s logistics and warehousing industries are rapidly modernizing. Many companies now use plastic pallets instead of traditional wooden ones. To produce these pallets efficiently, a hot plate plastic pallet welding machine or a heavy-duty ultrasonic welding machine is applied for joint fusion and reinforcement. The result is a strong, recyclable, and long-lasting pallet suitable for export logistics.

Consumer Electronics and Appliances

Vietnam has become a manufacturing hub for electronics brands like Samsung and LG Electronics. In these factories, the ultrasonic welding machine is essential for sealing small plastic housings, speaker components, and wearable devices with precision.

4. Local Market Dynamics and Supply Chain

The local supply chain for ultrasonic welding machines in Vietnam remains developing. While a few domestic firms provide simple hand welders, most high-precision systems are imported from China, South Korea, Japan, and Europe. Dizo Ultrasonic Technology has actively supported Vietnamese manufacturers by offering custom ultrasonic welding solutions that match local production needs and budget.

Dizo provides:

- Customized ultrasonic welding systems with local service support

- Free sample welding tests for Vietnamese customers

- Lifetime technical assistance and training

- Fast delivery to industrial zones such as Bac Ninh, Hai Phong, and Binh Duong

5. Future Outlook: Ultrasonic Welding Machine Demand Forecast

According to the U.S. Department of Commerce, Vietnam’s industrial automation market is expected to grow at over 12% annually through 2030. The ultrasonic welding machine market will benefit directly from this trend as more factories adopt high-speed, energy-efficient production lines.

Key growth areas include:

- Electric vehicle component welding

- Smart home device production

- Food packaging and medical device manufacturing

6. How to Choose the Right Ultrasonic Welding Machine for Vietnam

When choosing an ultrasonic welding machine for your Vietnamese factory, consider the following:

- Material compatibility (ABS, PP, HDPE, etc.)

- Part size and geometry

- Production volume

- Local service and spare parts availability

For cost-effective solutions and technical advice, visit Dizo Ultrasonic’s contact page and request a customized consultation.

7. Conclusion

Vietnam’s growing industrial ecosystem offers a huge opportunity for ultrasonic welding machine suppliers. As more factories prioritize automation, product quality, and sustainability, the adoption of ultrasonic welding technology will accelerate across sectors. With reliable partners like Dizo Ultrasonic Technology, manufacturers in Vietnam can confidently enter the era of smart production with innovative, efficient, and eco-friendly ultrasonic welding machines.

Learn More

8. Competitive Landscape of Ultrasonic Welding Machines in Vietnam

The Vietnamese market for ultrasonic welding machines is still in its early growth phase but evolving rapidly. Over the past decade, several international suppliers have entered the country through partnerships, distributors, and direct investment.

Major global players such as Branson (Emerson), Sonics & Materials, and Herrmann Ultrasonics have established regional distributors in Hanoi and Ho Chi Minh City. Meanwhile, Chinese and Korean manufacturers, including Dizo Ultrasonic Technology, offer competitive pricing and custom design advantages — making them popular choices for local factories.

Local Distributors and Agents

A growing number of local engineering companies now represent international ultrasonic welding machine brands. For example:

- TechCo Vietnam — distributor for German and Korean welding equipment.

- Automation & Engineering JSC — integrates ultrasonic welding machines into robotic production cells.

- Dizo Ultrasonic Vietnam Partner — provides after-sales service, installation, and operator training for custom systems.

However, most factories still rely on imports for high-precision ultrasonic welding machines, especially for automotive and medical-grade products. As local expertise grows, integration and maintenance services are expected to become more localized.

9. Government Policies Supporting Smart Manufacturing in Vietnam

The Vietnamese government actively promotes automation and technology transfer in its Ministry of Industry and Trade (MOIT) programs. Initiatives such as “Make in Vietnam” and “National Industry 4.0 Strategy” aim to reduce reliance on manual labor while improving manufacturing efficiency.

Under these initiatives, businesses investing in automation — including ultrasonic welding machines — can benefit from:

- Tax incentives for machinery imports and technology investments

- Favorable credit for equipment financing

- Training programs for engineers and operators

- Government-supported industrial clusters with logistics advantages

More information can be found on the official site of the Government of Vietnam.

10. Economic Benefits and ROI of Ultrasonic Welding Machines

Investing in an ultrasonic welding machine offers significant economic advantages over traditional methods such as gluing or screw assembly. These benefits are particularly important for factories in Vietnam where cost control and efficiency directly impact export competitiveness.

Key ROI Factors

- Reduced Labor Cost: One ultrasonic welding machine can replace 3–5 manual operators in repetitive tasks.

- Faster Production Cycle: Typical welding time is 1–3 seconds per joint, compared to 15–30 seconds for gluing.

- Lower Energy Consumption: Ultrasonic energy converts directly into mechanical vibration, minimizing heat loss.

- Reduced Defect Rate: Computer-controlled ultrasonic welding machines ensure consistent results.

- Eco-Friendly: No fumes, adhesives, or consumables — ideal for ISO 14001 and cleanroom compliance.

A study by ResearchGate shows that adopting ultrasonic welding can improve overall manufacturing ROI by 20–40% within 12 months of installation.

For example, Dizo’s ultrasonic welding machines integrate smart control systems and servo drives to maintain stable output across production batches — critical for exporters targeting EU and U.S. markets.

11. Trends Driving the Ultrasonic Welding Machine Market in Vietnam

Shift Toward Automation and Smart Factories

Vietnamese manufacturers are increasingly adopting ultrasonic welding machines as part of broader automation efforts. Integration with robotic arms and PLC systems allows real-time monitoring and quality assurance. As a result, the total cost of ownership (TCO) decreases while production uptime increases.

Environmental and Regulatory Compliance

With Vietnam tightening environmental regulations under MOIT and MONRE policies, non-toxic and energy-efficient technologies such as ultrasonic welding are being prioritized.

Many international companies relocating from China to Vietnam prefer ultrasonic welding machines because they meet both environmental standards and high-volume production requirements.

Rise of Local Technical Expertise

Universities such as Hanoi University of Science and Technology now include ultrasonic and automation modules in their mechanical engineering programs. This new generation of engineers will further strengthen Vietnam’s capability to design, operate, and maintain ultrasonic welding machines.

12. Challenges and Barriers

Despite its rapid growth, the Vietnamese ultrasonic welding machine market still faces several challenges:

- Limited local production: Most equipment is imported, increasing initial investment costs.

- After-sales service gaps: Some foreign suppliers lack localized support and spare parts.

- Operator training needs: Skill gaps remain in advanced machine tuning and material testing.

Companies like Dizo Ultrasonic Technology bridge these gaps by offering training, maintenance, and customized welding solutions directly to Vietnamese clients.

13. Future Development: Localization and Smart Integration

The next stage for Vietnam’s manufacturing sector will be localization of ultrasonic welding machine assembly and service. Partnerships between foreign and Vietnamese enterprises will enable cost reduction, quicker lead times, and job creation.

Moreover, smart manufacturing systems using IoT and AI-based monitoring are being integrated into advanced ultrasonic welding machines. This allows predictive maintenance and data-driven optimization — features already being implemented by Dizo Ultrasonic in its next-generation models.

14. Conclusion: Vietnam’s Bright Future for Ultrasonic Welding Machines

The demand for ultrasonic welding machines in Vietnam will continue to expand as the country strengthens its position as a global manufacturing hub. Supported by government initiatives, rising FDI, and growing technical expertise, the ultrasonic welding market is poised for exponential growth.

Whether producing automotive parts, medical components, or plastic pallets, Vietnamese factories will increasingly depend on reliable ultrasonic welding machines to deliver precision, speed, and sustainability. Dizo Ultrasonic Technology remains committed to providing the right equipment and expertise to help local manufacturers succeed in this evolving landscape.